I never know what I’ll come across in the blur of the busy-as-a-carnival-midway floor of the Mid-America Trucking Show, which concluded its annual run last weekend in Louisville, KY.

Well, I did know that I could at least count on getting a cuppa Joe that rose well above the caffeinated swill that gets served up everywhere else in the Kentucky Exhibition Center if I looked upBryan Johnson, senior manager-- Marketing & Communications for ZF North America, Inc. of Northville, MI, at their strikingly sleek exhibit in the main hall.

Allow me to digress to note that the Michigan-based firm’s parent ZF Group was formed in Friedrichshafen, Germany way back in 1915 to supply gearwheels and transmissions for the airships of none other than Count von Zeppelin. (“Zahnradfabrik” translates to “gear factory”).

Nearly a century later, gearing remains a ZF linchpin-- as the company is a major global supplier of driveline and chassis components for cars and commercial vehicles. According to ZF, it is among the top ten companies on the ranking list of the largest automotive suppliers worldwide.

Perhaps of greater importance to its OEM customers is that ZF is so determined to “continue to be successful with innovative products” that it annually invests about 5% of its sales in R&D.

Once he’d dispensed some prime java and a joke or three, Bryan led me over to a large but understated display that quietly heralded ZF’s newest technological tour de force for commercial vehicles.

Modular automatic

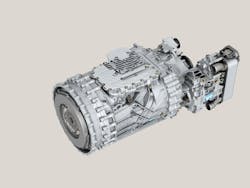

The rare marketing guy who is not easily given to hyperbole, my interest in all the gunmetal-gray components floating before me became especially piqued when Bryan remarked that what ZF was showing off was nothing less than a “revolution” in technology for heavy trucks—the TraXon modular automatic transmission system. He also allowed that that ZF was “seeing a lot of interest in it here at the show.”

Of course, truck OEMs and the customers they serve will ultimately determine whether or not and to what degree the TraXon is adopted. To be sure, they will have a lot to consider when diving into the details of this new design.

According to ZF, the TraXon delivers more torque as well as a higher gear spread and greater efficiency via a completely new basic transmission enhanced by a modular concept that enables fitting to a broad range of applications.

The company’s news release detailing the TraXon makes the interesting claim that it “combines several contradictions at the same time: It offers more torque, without compromising the power-to-weight ratio; it has a higher gear spread while the noise quality was improved; and, depending on the application, it can not only be driven by a dry clutch but also by a hybrid module, dual-clutch module, or a torque converter clutch. Furthermore, it can be combined with an engine-dependent PTO”

ZF also pointed out that for the base TraXon transmission, it developed its PreVision GPS shifting strategy, which it said “works in an anticipatory and especially fuel-saving way thanks to a GPS connection and an interface to navigation data.”

"With the TraXon we aim at sustainability,” said ZF’s Rolf Lutz, the member of the Board of

Management responsible for the Commercial Vehicle Technology Div., in a statement. “The development for the current market launch focused on a further increase of economy and customer benefit as well as the suitability for a range of applications which is as broad as possible."

Core transmission

The TraXon’s “basic” transmission features “very compact dimensions” with a splitter group, main group, and range-change group as well as two countershafts and one main shaft.

ZF indicated that this “space-saving design in combination with the newly designed gearsets that turns the TraXon into a benchmark in terms of the power-to-weight ratio.” That is to say, the automatic gearbox can transmit torques considerably above 2,200 lb-ft (3000 Nm).

The TraXon will be offered either as a 12- or 16-speed unit with both available as direct drive or overdrive versions. ZF also pointed out that the transmission concept allows for two additional reverse gears—enabling it to offer the TraXon with a total of four reverse gears optionally. “These enable longer, quicker reversing for special applications, such as trucks which are used at highway construction sites,” the company explained. “The TraXon basic transmission [has] a transmission efficiency of about 99.7% (Direct Drive).”

Also, according to ZF, all versions of the TraXon basic transmission have a “very high transmission spacing, enabling the driver to maneuver the truck in a balanced and comfortable way without the transmission becoming more prone to wear, e.g. due to excessive load on the clutch.”

The company also said its development engineers “managed to considerably reduce the noise development” of the TraXon compared to its AS Tronic gearbox by an average of 6dB by way of a new gearing design, innovations for the transmission housing and by integrating an anti-rattling damper.”

Modular variables

According to ZF, a key advantage of the TraXon is its modular transmission design. This makes it possible to combine the basic transmission with five starting or shift modules to “make the transmission more economical in practice, giving manufacturers and fleet operators the best possible flexibility for every application and increasing the comfort for the driver.”

Along with the single and twin- plate dry clutch for applications with “particularly high torque requirements,” ZF will offer the TraXon Hybrid—which it said will be the first hybrid module ever available for heavy commercial vehicles.

A 120kw electric motor and a separating clutch enable all the hybrid functions, which include recuperation, electric driving, boosting and start-stop. The electric motor can also be used for supplying power to additional units, such as for cooling. In addition, the hybrid will handle cab hotel loads when the truck engine is keyed off.

"Studies have shown that the use of hybrid drives in heavy trucks bears considerable savings potential", pointed out Winfried Gründler, who is responsible for Truck &d Van Driveline Technology at ZF's

Commercial Vehicle Technology Div. "It is true that the roughly 5% fuel savings are below the savings that can be achieved in delivery traffic. With the considerably higher mileage and fuel consumption of heavy trucks, hybrid technology is nevertheless an economical solution that diminishes resource use and pays off within a reasonable time period."

TraXon Dual

By combining the TraXon base transmission with a dual-clutch module and marketing it under thename "TraXon Dual,” ZF contends it is ready to meet a “future trend” with truck builder: “In order to save fuel, very long rear axle ratios can be installed that uniquely reduce the engine speed in the highest gear. However, this would increase the shift frequency with ordinary automatic transmission systems because the next lowest gear already has to be selected on slight uphill gradients. With the dual clutch module, it is possible to perform these downshifts and upshifts in the highest gears under load and without torque interrupt—as opposed to the shifting process in conventional automatic commercial vehicle transmissions. These comfortable and nearly unnoticed gearshifts also optimize fuel consumption.”

ZF also related that the TraXon base transmission can be combined with a torque converter clutchfor use in heavy road tractors. The "TraXon Torque" can “start wear-free with high input torques and stands for smooth and comfortable maneuvering at low life cycle costs.” Optionally available will be an engine-dependent PTO installed between the transmission and thee engine.

The company said its engineers have developed a standard software platform for the transmission control unit that can be used in all TraXon variants. It draws on a number of sensors to determine the pitch, direction of rotation, or speeds, “thereby enabling innovative transmission functions such as the anticipatory shifting strategy, rolling function, and more comfort when maneuvering or starting.”

GPS linking

According to ZF, its “anticipatory GPS-based driving strategy-- PreVision GPS— will prove to be a trailblazing innovation. ZF gives truck manufacturers the opportunity to link up the transmission with GPS data and digital map material. With the corresponding integration in the vehicle, PreVision GPS prevents gearshifts that may be unnecessary within the context of the terrain— for example when a conventional transmission control unit shifts up a gear before an uphill gradient or a narrow bend, just to shift down to a lower gear shortly after.

ZF called TraXon's aforementioned “rolling function” a “sensible feature on slightly sloping freeway or rural roads.” The company said that as the transmission goes out of gear, the driveline is decoupled during the rolling phase and the engine is running idle, “so possible drag losses are avoided, leading to corresponding consumption and emission savings.” In addition, a topography-based control “immediately detects steep slopes and applies the engine and transmission brake instead of the rolling function to preserve the service brakes,” ZF added.

"ZF's new TraXon transmission is the answer to all currently known megatrends in long-distance traffic,” summed up Rolf Lutz. “The greatest possible flexibility with many variants in a very broad application range leads to low operating costs because the transmission increases the reliability and reduces fuel consumption."

ZF's test vehicle for its TraXon modular automatic transmission system.

Follow me on Twitter: @David_L_Cullen