If you are considering—or being pushed into—new zero-emission powertrain technologies, you can’t start planning too early. Though the motors are simpler than today’s complex diesel systems, your fleet operations might need more thought.

“One of the biggest pieces of advice we often give to our customers is to start early,” Trish Reed, Navistar VP of zero emissions, told FleetOwner. “When we’re talking about zero-emission vehicles, we’re no longer just talking about the equipment. We’re talking about route analysis, infrastructure evaluation, charging installation, discussions with local utilities—the list goes on.”

The potential zero-emission vehicle landscape is broad. It’s not just battery-electric vehicles. Dozens of hydrogen-powered, fuel-cell-electric vehicles are already in operation in California. And engine-makers, such as Cummins and Bosch, are developing hydrogen-powered internal combustion engines for heavy-duty trucks. There are other low- and near-zero emission fuels, such as natural gas and renewable diesel.

See also: New freight corridor strategy maps future of zero-emission fleets

More options, more planning

“The future landscape of ZEVs is pretty broad when looking at the sources of propulsion,” Len Copeland, product marketing manager for Daimler Truck North America’s Detroit brand, told FleetOwner. “If you look at diesel configurations today across many fleets, you will see many configurations. Seeing different solutions based on individual needs will continue into the future.”

Copeland said electric configurations fit best with regional operations right now. “These electric configurations will spread into some areas of long-haul applications that will also likely have units powered by H2 fuel cell setups and then hydrogen combustion for heavier and vocational types of applications,” he said. “Just like today, I would say to spec vehicles for your application, and DTNA is committed to helping find the best propulsion source for your specific need.”

All of these propulsion options can be daunting. That’s why Copeland and other OEM executives said it’s easiest to go right to the source as you start to plan out your fleet’s zero-emission options.

“This is where discussions with customers and early engagement in the sales process become key,” Sarah Abernethy, Kenworth powertrain marketing manager, told FleetOwner. “Understanding the intended route is a critical first step in the discussion, and alongside that—talking through fueling and infrastructure will help ensure success with ZEVs.”

See also: Mack MD Electric production underway as early fleet operations begin

Infrastructure lags for heavy-duty

Infrastructure can be the biggest hurdle fleets face when adding in non-diesel equipment. Long-haul trucks can find diesel along any major road in the U.S. However, finding a high-powered electric truck charger or hydrogen outside a dedicated distribution center is rare.

“The technologies are being deployed, and the industry needs scale for the infrastructure to be built,” Abernethy noted. “Every day, we get closer.”

California has the most H2 fueling options, with more public hydrogen stations expected to come online in the Golden State this year. Public heavy-duty electric truck chargers are also rare, so fleets need to plan ahead before investing in these emerging technologies.

“On the battery-electric side, we continue to take a consultative approach with our customers, ensuring that we match the right truck to their application," Johan Agebrand, Volvo Trucks North America’s product marketing director, told FleetOwner. He said Volvo Trucks offers strategic route planning guidance, access to charging hardware through its Vendor Direct Shipping program, and end-to-end infrastructure support through its Turnkey Solutions partners.

VTNA now has more than 50 certified EV dealers in 27 states and provinces. Another 40 dealers in the U.S. and Canada have started the certification process, Agebrand noted. Volvo aims to sell 50% zero-emission vehicles by 2030 and 100% by 2040.

“The product offering is only one portion of the equation,” Agebrand explained. “In order to reach a 1:1 scale in great numbers of zero-emissions vehicles, infrastructure improvements must continue and must increase in speed for our customers to scale at their desired rate. Incentives and grants are also critical components in the adoption of zero-emission vehicles.”

It’s about more than the truck

Agebrand said dealers can help fleets assemble their decarbonization puzzle pieces.

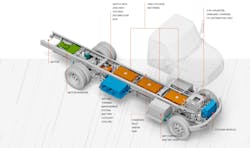

“The truck is a very small piece of the total equation,” he explained. “It’s critical first to understand where they’ll be deploying a ZEV. We want to make sure that it’s in an area serviced by one of our certified EV dealers. Then, understand exactly what the routes and type of cargo being utilized are. Does the customer need a six-battery pack configuration, or is a four-battery pack sufficient for their operation?”

From there, they focus on utility timelines to set up depot charging or find other ways to power the EVs, such as charging-as-a-service options. “Zero-emissions deployment is a complex and changing landscape,” Agebrand added.

See also: The future of trucking looks like both BEVs and diesel

Beyond infrastructure, Kenworth’s Abernethy noted that fleets should consider how weight and wheelbase impact BEVs and FCEVs “to ensure the truck is set up for success and will meet the customers’ needs.”

Navistar’s Reed said International Truck dealers take a “holistic approach to transition to help guide the customer.”

She added: “We also understand that based on vehicle application, usage, and customer motivations, the speed to carbon-reduction goals will vary. So, if there was one thing that is different when spec’ing out a zero-emissions vehicle, it would be that you have a lot more to consider than just the vehicle.”