NASHVILLE. At any major trucking trade show, the exhibition hall will feature dozens of vendors who market various solutions for improving fuel economy and saving on fuel costs. Mike Roeth’s pitch at this week’s Technology & Maintenance Council (TMC) annual meeting is unique: He’s giving his product away, and he has the data to prove it works.

As executive director of the North American Council for Freight Efficiency (NACFE), Roeth leads Trucking Efficiency, an initiative set up by NACFE and the Carbon War Room (CWR) that aims to double the efficiency of the North American trucking fleet. To achieve this goal, the organization evaluates current technologies, discusses challenges and best practices for their adoption, and provides figures on performance gains and payback periods.

Simply, the program is designed to help fleets make better decisions and, collectively, save billions of dollars.

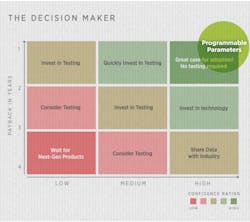

The fifth and latest “confidence report,” focused on electronic engine parameters, has just been published. And, based on Trucking Efficiency’s grid to assess whether a technology will be effective, optimizing engine settings is a fuel efficiency sure thing.

Speaking to trade media in Nashville for TMC, Roeth compared a truck engine to a smart phone: “Once you’ve gone through the effort of programming them, you love them,” he said.

The catch is taking the time to understand the many possibilities for setting up an engine to suit the truck’s operations.

As explained by NACFE Program Manager Dave Schaller, there are more than 100 different parameters that control a modern diesel engine. A fleet survey found three levels of complexity as to how these settings are commonly used.

Most basically, an engine is left with the factory default settings. The middle level comprises changes to a few obvious settings, such as a vehicle speed limit. At the top, the optimized level means a fleet has worked with an engine maker or a fleet expert to fully exploit the array of options.

Moving from the basic settings to the middle level can deliver a 3 to 5 percent improvement in fuel economy, Schaller continued, while a fully optimized engine can deliver an 8 percent improvement – or even more.

“This is pretty exciting,” Schaller said. “I don’t know of any other area here at TMC that doesn’t cost anything extra, doesn’t add extra weight to the truck, and it theoretically doesn’t add any maintenance – it doesn’t break. So it’s a really neat area.”

The challenge, of course, is getting those settings right – especially when a change to one setting can impact the performance of another. And the proprietary programming that underlies the improved fuel economy of fully integrated powertrains adds even more complexity.A discussion about a fleet’s ideal operational profile should be part of ordering a new tractor, with the parameters to be set accordingly at the factory. But that’s often not the case, the researchers found. And it’s also not uncommon for the parameters to be reset at a specially center for finishing touches, or even in final prep at the dealer.

Complicating the matter, OEMs often use different terms for essentially the same settings.

For those fleets that do pay attention to engine settings, the survey found that templates often are used for simplicity and consistency. However, the survey also found “a huge drop off” in engine optimization that corresponds to fleet size.

As an electrical engineer who helped develop programmable engine technology, Schaller noted that “this is way more complex than it needs to be.”

“What we know is that optimizing the parameters is definitely worth the effort,” Schaller said. “It pays back. It enhances fuel economy and saves fleets money, but the complexity of optimizing is preventing many fleets from enjoying the benefit.”

To help fleets take advantage of the technology, the confidence report includes a variety of tools and recommendations, while Roeth offers additional thoughts on FleetOwner.com’s IdeaXchange.