Logging in at almost 1,700 pages, it'll be sometime before all the details in last week's Greenhouse Gas Phase 2 (GHG 2) regulations are widely known. However, there weren't really many surprises in the final rule. Most of the proposals had been telegraphed by the government months ago. So at this point, it's really all about the details as industry experts dig in to the text and start plotting their emissions and fuel economy strategies for the next decade.

Because make no mistake about it, more than anything else in the world right now, GHG 2 will dictate the development and deployment of next-generation trucking powertrains over the next 10 years.

And, based on what is widely known about GHG 2 now, we can go ahead and make some educated cases as to what the next decade will bring about in terms of powertrain technology.

First off, it's important to note that GHG 2 actually gives OEMs and component suppliers a fair amount of leeway as to how they'll chose technology pathways to get to compliance. Which means we can expect to see OEMs play to their strengths initially, before they sink their teeth into the more difficult aspects of the new rule.

So, for starters, we'll see "easy" challenges tackled very soon -- before summer is over, in fact -- as OEMs start to concentrate on tractor and trailer aerodynamics in a more integrated and complimentary fashion. Look for a whole lot more body sculpturing as sharp edges fade away and gentle, curves designed to expedite airflow take their place.

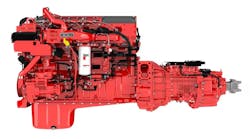

Enhanced system integration is another easy way to optimize GHG 2 performance right away. So look for more efforts from OEMs and suppliers like Cummins and Eaton to fine-tune existing integrated drivetrains and enhance performance wherever they can.

Looking out a bit farther, I'd say it's a safe bet that before too long, fully-integrated, fuel-economy optimized "smart" drivetrains will be the standard powertrain option on new tractors. The same goes for automated manual transmissions (AMTs), too. It's very likely GHG 2 will be the rule that effectively kills off manual transmissions in heavy-duty trucking once and for all. I suspect that very soon, AMTs will be standard equipment on new trucks. And if you want a manual gearbox, you'll have to spec it. And you may even find yourself paying a premium for it, to boot.

Once again, OEMs and powertrain suppliers will be able to "bank" emissions credits for early compliance. And they will be able to "spend" those credits later on as GHG 2 starts to take hold in the industry.

Moreover, OEMs and suppliers will be scored on the fuel efficiency and emissions compliance for entire annual builds. This means -- in theory, anyway -- that they can build X number of not-so-fuel-efficient trucks, as long as they build enough super-fuel-efficient trucks during the same time span to make sure the overall GHG 2 performance numbers average out when everything is said and done at year's end.

So, that means that it is possible some OEMs will continue to build long-nosed, slab-grilled tractors in the coming year.

But I wouldn't bet on it. In fact, I think it's entirely possible that GHG 2 will be the final death knell for most, if not all, long-nose conventional tractors. Even though many of those trucks work in applications where aerodynamics simply don't matter (heavy haul, for example) it's very likely OEMs will decide to simply offer specialized aerodynamic tractors for those roles in the near future, and just side-step any GHG 2 penalties they would've incurred for building those old style trucks in the first place.

That gets most of the low-hanging fruit out of the way. But there are a couple of new technologies that OEMs are going to have to figure out how to refine to get to the really aggressive parts of GHG 2 when the law goes into full effect in 2027: namely waste heat recovery systems and hybrid drivetrains.

Waste heat recovery systems, as the name implies, are systems designed to capture heat energy produced by the engine as the truck is moving down the road. Previously, that heat energy was simply lost without contributing anything useful to the drivetrain's overall efficiency, as anyone who's ever placed their hand on the hood of a car or truck just after its been switched off can attest. These systems will capture that heat energy and put it to work, most likely by powering auxiliary systems on a truck such as the HVAC or engine cooling fan.

As any driver knows, trucks burn more fuel in lower gears as the powertrain works hard to get a fully-loaded rig up to highway speed. Once at cruise speeds, the engine becomes highly efficient and fuel burn decreases significantly.

That's why GHG 2 is forcing OEMs to look at developing hybrid-electric drive systems to provide additional torque to the wheels during the launch phase and help decrease big fuel burn spikes. Unlike internal combustion engines, electric motors provide 100 percent torque right away. Which means that extra power can be put to instantaneous use launching a truck.

Both of these systems featured prominently on the recent Super Truck vehicle development project jointly conducted by the trucking industry and the Federal government. And while the systems work -- they are expensive, and add weight and complexity in return for very modest fuel economy gains. So the pressure will be on OEMs to find ways to make these systems perform better, more reliably while being lighter, less complex and affordable. It's a tall order -- likely the most difficult technological challenge OEMs will face over the coming decade.

All in all, it seems that in the short run, we can expect GHG 2 to accelerate already well-established powertrain trends in trucking, with more cutting edge technology coming on line later on. Keep in mind however, that GHG 2 will not be the only guidelines influencing truck design over the next decade. Other trends, such as autonomous and platooning technology, as well as rapidly evolving vehicle communications systems will certainly leave their marks, too.

The next generation of heavy-trucks will be here sooner, rather than later. And they will feature technology that was unheard of in the automotive world just a few short years ago. The challenges for fleets and OEMs alike will be significant. But, as usual, the industry will have no choice but to collectively roll it's sleeves up and take them on, one by one, and solve them all.