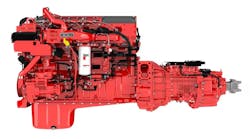

NASHVILLE. Eaton Corp. and Cummins Inc. plan to offer a new heavier-duty rating for their joint Smart Advantage powertrain in the third quarter this year, along with other several other joint powertrain combinations aimed at the heavy-haul trucking segment starting in April.

Eaton and Cummins explained during a press conference here at the 2106 Technology & Maintenance Council (TMC) annual meeting that they are targeting the release of a Smart Advantage series transmission with a maximum gross commercial weight [GCVW] of 80,000 lbs. with a 1,850 lb.-ft. torque rating for August this year.

“It’s a rating aimed at providing better performance, specifically on grades, offering improved acceleration as well as better residual value,” said Ryan Trzybinski, Eaton’s product planning manager. “It’s providing extra torque on the top end of the gears but down in the low end, too.”

In April, Eaton and Cummins will release an additional rating 1,850 lb.-ft. of torque for the 400 to 475 hp Cummins ISX15 when mated to one of three Eaton transmission models: an Eaton Fuller Advantage C-Ratio 10-speed transmission, an Eaton UltraShift PLUS MHP 13-speed transmission, or an UltraShift PLUS MXP 18-speed transmission.

Mike Taylor, GM for Cummins global powertrain, noted that the Advantage transmission tops out at a GCW rating of 110,000 lbs., while the UltraShift PLUS MHP is rated at 140,000 lbs., with the MXP having an unlimited“We cannot impose one specification to meet all our customers’ needs,” stressed Mario Sanchez-Lara (at right), director of technical sales support for Cummins. “There are so many different factors affecting their operations: loads, speeds, road conditions. So we are offering more options to them and clearly the many [trucking] niches] will benefit.”

He noted in particular that the new joint heavy-haul joint powertrain packages on the way from Cummins and Eaton were designed after feedback from Canadian fleets who desired heavier engine rating bands to gain more “downspeeding” opportunities.

“The 1,750 lb.-ft. torque rating worked for them, but they wanted more torque in the lower gears,” Sanchez-Lara said. “That is the feedback we got and we translated that into action. It brings in more performance without sacrificing fuel economy.”

“Clearly these fleets are not as fuel economy-minded as others; they are trying to haul heavy loads up over mountains,” Cummins’ Taylor added. “But we are trying to help them maximize fuel economy where we can.”

Eaton is also integrating its new GearLogic technology with Cummins ADEPT electronic features; a suite of features crafted for the ISX15 engine so it can better interact with automated manual transmissions (AMTs).Eaton’s Trzybinski (at right) said that GearLogic will allow for the “smoother delivery” of various performance functions, such as Hill Start Aid, engine overspeed protection, enhanced engine braking, Smart Coast, Blended Pedal, and vehicle acceleration management (VAM).

“We’ve spent a lot of time on the hardware and a lot of time on the software, all aimed at providing a more complete value chain from front to end to take care of the customer start to finish,” Cummins’ Taylor said.

That electronic collaboration is also proving critical from a driver retention standpoint, Eaton’s Trzybinski said.

“Driver retention is probably one of the biggest macro factors along with fuel economy that has us at the table with those solutions,” he explained. “If the drivers like the feel [of the transmission in operation] they stay with the fleet. Not only does that give the fleet better fuel economy, they don’t have to spend money finding and hiring new drivers. It is real money saved.”

That “value chain” also now includes more joint support as well, as the two companies are combining the Cummins Care program with Eaton’s Roadranger support network, integrating the 24/7 call-centers of both companies, sharing current diagnostics tools and jointly developing new tools, plus cross-training their respective sales and service teams.

The big benefit to bringing both Eaton and Cummins experts up on the line simultaneously is the time savings, noted Scott Davis, aftermarket and technical services director for Eaton’s Roadranger network.

“No longer is it, ‘this is an engine problem, call them’ or ‘it’s a transmission problem, call them’ situation,” he said. “Now we are both on the line trying to solve a problem. It’s a big benefit for technicians especially as they are not wasting time on the phone away from a repair.”

Two other joint efforts noted during the Eaton/Cummins press conference:

- Eaton and Cummins are releasing a Smart Advantage application available via the Internet or a smart phone to help customers get a more finely-tuned set of options when spec’ing a Smart Advantage powertrain. Eaton’s Trzybinski noted that specific fleet inputs such as average road speed, vehicle weight, terrain, stop/start frequency and even tire size put into the app provides not just one but two powertrain options to give customers more options.

- For the medium-duty market, combination powertrains featuring the Cummins ISB engine and Eaton’s new Procision dual-clutch AMT are now in production and being offered by Navistar International, school bus makers IC Bus and Blue Bird, as well as Freightliner medium-duty models.