INDIANAPOLIS. Cummins Inc. continued building on its legacy of powering medium-duty trucks as the company unveiled the next generation of its B Series and L9 engines here in its headquarters city at the NTEA Work Truck Show Tuesday afternoon, March 1.

These engines are to be "the next chapter in a long line of diesel and natural gas products proven in applications all around the world," according to Cummins. Over the past 32 years, Cummins has produced more than 16 million midrange engines, drawing from extensive real-world experience to innovate and refine these engines for greater reliability and dependability.

"This B engine has really redefined the way that we use diesel engines in commercial vehicle applications," said Srikanth Padmanabhan, vice president for engine business at Cummins. "Every 15 seconds, a B Series engine comes off of our production line," he added, calling the series an American classic.

"In our mind, in many, many ways, the B Series is the 'blue jeans' of the American trucking industry. That is, it is here to stay, and it'll never be out of style," he said at a press conference.

"Medium-duty truck customers have made Cummins their engine manufacturer of choice due to the unparalleled uptime they have experienced with our B and L Series engines. This is the legacy that Cummins has created over nearly a century of engine innovation and more than 30 years of B Series and L Series availability," said Brett Merritt, executive director of Cummins' on-highway business.

2017 B6.7

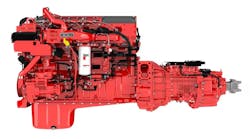

The B6.7, with 200-325 hp and 520-750 lbs.-ft. ratings ranges, is the next generation in a proven line of B Series engines dating back to the introduction of the 6BT5.9 in 1984. Stable architecture design from experience gained over decades leads to further refinement to deliver one of the most dependable engines in the industry.

New for 2017 is an increase in fuel economy for the entire range of B6.7 ratings. Optimized for stop-and-go duty cycles, the B6.7 efficiency ratings — 200-260 hp — offer an increase in fuel economy of up to 7% over the current product.

The B6.7 performance ratings — 280-325 hp — also offer enhanced efficiency while still meeting demanding duty cycles. Customers can expect up to a 5% increase without sacrificing power. Further fuel-economy improvements can be realized with innovations like the Stop-Start system. This technology allows the engine to operate only when necessary, saving fuel and creating a quieter ride for the driver.

2017 L9

With ratings from 260-380 hp and 720-1250 lbs.-ft., Cummins says the 2017 L9 will continue to lead its class with the highest power-to-weight ratio, offering optimized ratings "for some of the toughest duty cycles." New for 2017 is a 350-hp/1,150 lbs.-ft. rating that maintains more power and torque across a wider rpm range — ideally suited for tough vocational duty cycles, according to Cummins.

"The L9 is a staple of the work truck environment and is powering the most severe duty cycles. If you go to any vocational application and open the hood, the L9 is most likely powering it," Merritt said. "The 2017's additional 350-hp, 1,150 lbs.-ft. version provides a broader power band in order to optimize the transmission to give both the fuel economy and performance balance that you need."

With some further enhancements in reliability on an already proven heavy duty design, Cummins predicts the L9 will continue to be "the productivity champion, especially in the most demanding work truck applications."

2017 Single Module after-treatment

The Single Module after-treatment system combines a diesel oxidation catalyst, diesel particulate filter and selective catalytic reduction systems into a single canister. The system features up to 70% reduction in footprint and up to 30% weight reduction over current after-treatment systems, Cummins says.

"Our customers said with after-treatments, 'Please, make them lighter, make them smaller and make them more efficient,'" Merritt told listeners. "With the 2017 single module after-treatment, we're going to deliver just that. So we're not just delivering increased emissions [reduction], we're also meeting customer needs."

Simple and optimized diesel exhaust fluid (DEF) dosing with Cummins' UL2 Urea Dosing System eliminates the need for engine coolant lines to and from the DEF injector, reducing installation complexity and allowing for easier serviceability.

The injector's proprietary atomization nozzle minimizes the risk of deposit formation, according to Cummins, and offers a freeze-robust design and improved reliability. Further, the company sized a range of systems for engine and rating to ensure "the most efficient operation for improved fuel efficiency across a diverse range of applications."

Support

All Cummins engines are backed by the largest and most capable support network in North America, with more than 3,500 authorized repair locations to service vehicles. Diesel and alternative-fuel experts can help get trucks out on the road faster and keep them there, according to the company.

Cummins Care is available 24 hours a day year-round at 1-800-DIESELS (1-800-343-7357).