I went for a crash course in engine lubricants, and boy, did I get it—along with an education in global energy markets, alt fuels, engine and emissions technologies, testing protocols and coming standards. The thing is, they all go together. And the takeaway from an intense couple of days around a lot of people with “Dr.” on their name tags is that we certainly shouldn’t take engine oil for granted, and we’d be making a big mistake to treat it as a commodity.

The occasion was last week’s Shell Lubricants global media event, featuring presentations from company scientists and engineers, marketing folks who made sense of those charts and graphs, and translators handling Spanish, Chinese, German, and Russian to make sense of it all for the international press who gathered in San Antonio.

The classroom was the conference center at the impressive Southwest Research Institute (SwRI) complex. It’s one of the largest applied R&D facilities in the U.S., and between the Shell and SwRI staff on hand, you couldn’t swing a cat without hitting a PhD.

Recess was at the nearby 2015 Shell Rotella SuperRigs event where there were fewer scientists but plenty of folks who’ve earned doctorate-level educations on the road.

The highlights from in between include:

- The long-lived CJ-4 engine oil standard is on its way out, making way for API Proposed Category 11 (PC-11), designed to provide improvements in oxidation stability, shear stability and aeration. There will be couple of variants when the standard comes out late next year or early 2017: PC-11A (likely to be called CK-4 when approved), which will be the replacement for CJ-4, and PC-11B (FA-4), lower viscosity or “thinner oils” formulated to work with newer engines and emerging technologies to maximize fuel efficiency. Shell’s handy explainer is here: WhatisPC11.com.

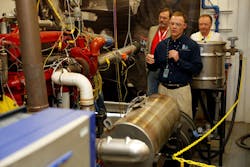

- Getting a product certified to meet any American Petroleum Institute (API) standard is a complex and expensive proposition, as we learned on a tour of an engine lab at SwRI. Big diesels, anchored to the floor in the testing rooms and hooked up to more tubes and monitors than any patient in intensive care, are stressed to the limit to compress the running time needed to evaluate performance. Once complete, the engines are torn down, evaluated and rebuilt to good-as-new standards—and the tests start over. These tests are expensive, at well more than $100,000 each (12,000 gallons of fuel per test is much of the cost), and each standard demands multiple tests—and all of these tests must be done for each product. It’s likely that most current CJ-4 formulations will fail at least one of the PC-11A tests—so Shell insists the engineering team’s validation work puts the Rotella line well ahead of the competition.

- Shell is also pulling out all of the stops to make sure the PC-11B formulation of the next Rotella variant will work well in older engines (EPA-07 and newer) along with handling the demands put on the latest diesel tuned to maximize fuel efficiency with powertrain stresses caused by downspeeding, for instance. The goal is to make lubricant management simpler for customers. Shell arranged a visit to a nearby dealership to witness the results of recent teardown demonstrating the effectiveness of one of the PC-11B candidate formulations. See the gallery: Teardown Evangelist: The art and science of engine disection.

- The price point for diesel may have stalled momentum in North America, but natural gas is currently powering more than 300,000 trucks in China—and that technology, well tested and mass produced, is likely to make its way into the North American market very soon.