Cryogenics 101: An introduction to a cleaner, quieter alternative

Cryogenically cooled trucks and containers have been in operation for years. In fact, carbon dioxide-cooled railcars in some shape or form date back to the 1960s. Many of those units are still in service, a testament to the durability of industrial cryogenic equipment.

Europe is the first region to take on wide-scale adoption of the cryogenic transport refrigeration unit (TRU). In North America, the cost of diesel and more governmental mandates on emissions control have resulted in cryogenically-cooled units garnering more attention than ever before.

Understanding the basics of these units and what the different options and offerings are can help you discern if cryogenically cooled TRUs are a financially viable option for your fleet.

The basics

These TRUs come in two flavors: liquid nitrogen and carbon dioxide models. For the most part, a system running each would be similar. The major difference between the two cryogens is the temperature they live at and the pressure they are kept at. Carbon dioxide needs to maintain pressure to avoid becoming dry ice and losing its liquid state. Carbon dioxide is also a “warmer” cryogen, boiling off at –109.3° F (–78.5° C) versus nitrogen, which boils at a colder –320.4° F (–195.8° C).

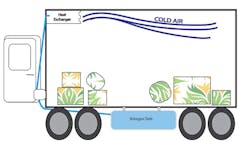

There are two types of designs: direct injection and indirect cooling. The direct injection system relies on a set of spray nozzles placed at the top of the trailer. These nozzles connect to the control unit, which reads conditions of the trailer and signals the supply system when it is necessary to spray the super-cold nitrogen or carbon dioxide gas into the trailer for maintaining proper temperature.

On the other hand, the indirect system relies on a heat exchanger for its cooling power. Heat exchangers are placed in various points throughout the trailer. Most commonly they are found at the front of the trailer wall similar to a conventional diesel unit. Some manufacturers have designed systems that are on the ceiling of the unit, too. The indirect cooling unit operates by running the super-cold liquid through a heat exchanger that draws the “cold” out and then is moved through the trailer by way of a fan. Both direct and indirect designs can be configured for multiple cooling zones for split-use trailers such as refrigerated and frozen units.

Mechanical versus cryogenic

Naturally, the question is, “How do these units stack up against the traditional diesel/coolant system?” The answers are, “it depends” and “pretty well.”

The cryogenic TRU does not have the emissions of a diesel unit, nor does it contain coolants that emit and need to be recharged. These units are also extremely quiet. With no engine, they are almost completely silent. Lack of noise and odor make these perfect for being placed in operation at an event site where consumers will be nearby.

Some of the not-so-obvious benefits include the ability to be more efficient at maintaining temperatures over time in a closed container. While these units use more “fuel” per Btu cooling to get to temperature after warming up, such as opening and closing of the trailer, they are able to cool the trailer more quickly.

These cryogenic TRUs also have a lower cost to operate. The drastic reduction in moving parts means little wear and tear to the system. In general, the only moving parts are solenoids and fans. This translates to lower cost of operation and less downtime/better utilization of fleet assets.

It should be noted that I don’t believe cryogenic TRUs are suited for all applications. The largest storage tanks on these units tend to top out at 1,000 liters. This is plenty of cooling power for a day’s travel, but not for a multi-day over-the-road situation. A depot configuration is ideal along with “return empty” loads.

The future

Why aren’t we seeing more of these units in the field? Just like all “new” technologies, there is an adoption cycle. Currently, some larger grocery chains and equipment makers are testing the units. A major hurdle is the supply chain for the cryogen itself. Both carbon dioxide and nitrogen are readily available in North America, but the storage equipment isn’t in place at distribution centers. The delivery infrastructure is a capital expense that needs to be factored into the overall cost of transitioning to cryogenic cooling and often takes time to prove out to corporate purchasing groups.

It is only a matter of time before many organizations and governmental agencies adopt a cleaner and quieter approach to mobile cooling. Cryogenic systems have evolved to the point of being a very viable and affordable option today and the foreseeable future.

Judson Voss serves as business development manager for Chart Industries Packaged Gas business unit (www.chartindustries.com). Chart provides engineered cryogenic solutions to many industries. Voss may be contacted at [email protected].

About the Author

Judson Voss

Judson Voss was business development manager for Chart Industries' packaged gas business unit. Voss now works as a Pardot and Salesforce consultant.