FirstElement brings heavy-duty hydrogen fueling capabilities to the masses

OAKLAND, California—FirstElement Fuel is opening a hydrogen fueling station near the Port of Oakland. The company unveiled its plans at the soon-to-open fueling station, which it said would be North America's first public hydrogen fueling station.

Placing the facility near the Port of Oakland was strategic. Thousands of Class 8 trucks travel around the California Bay Area ports daily, and Eugene Litvinov, director of commercial vehicle and hydrogen business development at Hyundai Motor North America, said that, often, trucks working in port and drayage operations “are on their third and fourth, or maybe even fifth life cycle, meaning they're older models and much more heavily polluting; they're having to idle a lot as they wait for their loads.”

Therefore, it is estimated that operating just 30 hydrogen fuel cell trucks in drayage operations at the Port of Oakland would eliminate almost 50 million lb. of CO2, reduce nearly 2 million gallons of diesel, and eliminate 300,000 lb. of other pollutants, according to Litvinov.

Overcoming obstacles to hydrogen fuel adoption

Opening the station to the public helps solve the “chicken or the egg” equation with hydrogen-powered vehicles, which is: infrastructure versus vehicle availability.

Ten years ago, Dr. Shane Stephens, FirstElement founder and chief development officer, said there were three obstacles to hydrogen-powered vehicle adoption: development of fuel cell stacks, hydrogen tanks, and infrastructure.

“The car companies have pretty much gotten to the fuel cell stack and the tanks, and they've solved those issues. The last outstanding thing is the infrastructure,” Stephens said. “That's why we founded this company over 10 years ago to develop that network of commercial hydrogen stations and help overcome that chicken and egg challenge.”

See also: Renewable diesel could cut emissions for much less than electrification

Once the public station opens in May, it can support more than 200 Class 8 hydrogen-powered trucks daily, according to the hydrogen supply and fueling company. FirstElement anticipates supporting this many trucks through a refill time of about 10 minutes per truck—on par with the time it takes to refuel diesel Class 8 trucks. One fleet operating 30 Class 8 Hyundai Xcient hydrogen trucks in the area has already committed to fueling at the station.

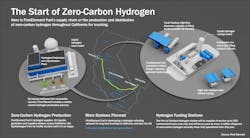

FirstElement’s initial financing came from automotive companies and public agencies in California. It has since acquired additional private funding of more than $340 million and more than $150 million from state and regional agencies. The company also owns more than $25 million of upstream supply assets to support its pioneering efforts in developing hydrogen infrastructure.

"We never saw ourselves getting into [the hydrogen upstream supply] business, but frankly, the systems that were out there for delivery and distribution of hydrogen left us hanging out to dry,” Stephens said. “They were not sufficient to meet customer demands and our demands, and we had several fuel supply disruptions with some of the providers that were out there. So we actually invested in trailers and some upstream supply assets so that we can fill those gaps.”

In addition to its own supply chain developments, FirstElement also operates its True Zero Hydrogen Innovation Center, which conducts research and development and in-house fabrication. While FirstElement’s operations are robust today, the 10-year process to get there took trial and error.

The road to public hydrogen fueling

FirstElement has worked on bringing hydrogen fueling infrastructure to market for 10 years, developing three types of hydrogen refueling stations. The first generation of hydrogen refueling station, launched in 2015 and 2016, only provided 200 kg of hydrogen per day with one dispenser. The station was primarily used for hydrogen-powered passenger cars. The station was designed by FirstElement’s equipment supplier and supports gaseous hydrogen.

See also: Scaling up AVs for the commercial vehicle industry

“We quickly saw that these [first-generation] stations cannot meet up with consumer demand whenever the cars began to enter the marketplace,” Stephens explained. “We had long lines for customers, four or five cars deep, so the last car in line there is going to end up waiting 20 or 25 minutes to fill.”

Gaseous versus liquid hydrogen

While gaseous hydrogen and liquid hydrogen both shine as a preferred fuel in certain applications, what makes liquid hydrogen easier to scale than gaseous hydrogen boils down to the fact that “gaseous hydrogen is very limited in how much you can fit into a delivery trailer,” Stephens said.

“In addition to that, when you arrive to a station to offload that hydrogen, you can only offload about half of it because it's compressed inside,” Stephens explained. “Then, as you start drying out the hydrogen, you draw down the pressure, so you're always left with a significant amount inside the trailer. That caused a very inefficient logistics system. We found that even for the small stations that filled about 40 cars a day, we sometimes had to do two or even three deliveries to meet the needs of the customer demand.”

In comparison, liquid hydrogen is much more dense, allows for the transport of up to 10 times more hydrogen, and nearly all of it can be offloaded at a station. Stephens explained that tanks storing liquid hydrogen also occupy less space at a station, contributing to a smaller footprint and fewer construction costs.

FirstElement shifted from gaseous hydrogen to liquid hydrogen after monitoring its customer experience at its gaseous hydrogen fueling stations. Fueling with gaseous hydrogen resulted in 30 to 40 minutes spent at the station, leading to frustrated drivers, Joel Ewanick, executive chairman of the board of directors at FirstElement, said.

FirstElement can “fuel four cars at the exact same time now with our new liquid stations, and that is very analogous to a normal gas station,” Ewanick said. “That was the whole idea: Replicate what they get with gasoline. We want to be the same location, and we want to have the same experience—get in and out in less than five minutes. And that's what we're able to do. The gaseous was never going to achieve that.”

Liquid hydrogen, while not available worldwide, is available in California via a production facility in Ontario. Further, Air Liquide built a liquid hydrogen production facility in Las Vegas, which is the source of the hydrogen for this particular truck stop, Ewanick said. However, that facility is “only a drop in the bucket of what we’re going to require for a station like this,” Ewanick said.

The second type of station is known as a high-capacity retail hydrogen refueling station and features FirstElement’s proprietary design. It’s capable of refueling up to 1,600 kg per day using four dispensers and liquid hydrogen.

Using knowledge gained from the first-generation station, FirstElement designed the second-generation station to support a commercially viable network of liquid hydrogen for fast fills and simultaneous refueling using a device known as a “cryopump.”

A cryopump takes liquid hydrogen, which is stored at the station, and converts it into cold, pressurized hydrogen in one step, Stephens explained. This simplifies the process of storing, moving, and pumping hydrogen into a vehicle, allowing FirstElement to more easily scale hydrogen infrastructure to support more—and larger—hydrogen-powered vehicles.

The cryopump “allowed us to go up in order of magnitude and scale 10 times larger in the amount of volume that we were able to deliver on a daily basis,” Stephens said. “We went from being able to [fill] 40 cars per day to being able to fill about 400 cars per day.”

The company currently has 41 retail station locations and 92 total dispensers to support more than 16,000 fuel cell vehicles across the state of California. It holds almost 90% of California’s hydrogen market share, Stephens said.

The soon-to-open third-generation station also features a FirstElement proprietary design, using two heavy-duty truck dispensers and four light- and medium-duty dispensers. The station can dispense 700 bar fills, the pressure equivalent of about 10,000 PSI. This ensures more hydrogen is dispensed into the vehicle.

While the average Class 8 truck will only need about 60 kg of hydrogen per refuel, according to Jerome Gregeois, director of commercial vehicle development at Hyundai America Technical Center, the truck station is capable of dispensing 18,000 kg of liquid hydrogen per day.

See also: Hyzon helps fleet cover its bases before implementing hydrogen fuel cell EVs

Scaling hydrogen infrastructure

While the world’s first public hydrogen fueling station, capable of fueling heavy-duty vehicles, hasn’t officially opened, pilot refueling at the site has resulted in more than 200 demonstration fills on heavy-duty trucks. Within the last 30 days, the site has completed more than 50 fills with more than 2,000 kg of total hydrogen dispensed.

FirstElement plans for more hydrogen truck stops, with two currently in development. Each truck stop will also feature a fueling island for light- and medium-duty vehicles—all open to the public for commercial vehicle charging. Stephens said that developing these stations will help support the adoption of hydrogen-powered vehicles in the commercial market.

About the Author

Jade Brasher

Senior Editor Jade Brasher has covered vocational trucking and fleets since 2018. A graduate of The University of Alabama with a degree in journalism, Jade enjoys telling stories about the people behind the wheel and the intricate processes of the ever-evolving trucking industry.