If patience truly is a virtue, truck drivers are often asked to be the most virtuous folks out there. They wait to turn onto busy roads, they wait in rush hour traffic, they even wait at weigh stations. And when they finally get their hauls to the warehouse, they’re stuck in detention, the indeterminate time it takes to unload and/or load the trailer. It could be two hours, or it could be six. A 2016 DAT survey found nearly two-thirds of drivers had an average detention time exceeding three hours.

“Dwell time is a problem,” said Matt Davidson, VP of product and marketing at Locix, a startup using technology to address the warehouse issue. “But just telling someone how long a truck has been there doesn’t solve the problem, it just quantifies how big a problem it is. We don’t know all the key ingredients holding up line.”

To find out what is really happening at the dock, Locix launched SmartDock, which seeks to cut the total amount of time a truck is at a shipper by adding inward and outward wireless cameras called HD Vision sensors hooked up to an artificial intelligence platform that monitors activity. The machine learning looks for certain patterns, such as a truck pulling into the dock, and then watches for inconsistencies, such as no activity around the truck for 30 minutes. The supervisor and other relevant workers receive alerts so they can act to remove any potential bottleneck.

The wait may be unavoidable, but the manager may also be able to use the real-time data to prioritize resources to a dock where a truck has been waiting the longest.

“It’s all about filling those gaps in communication,” said Davidson, adding the historical visual data can be compiled to better understand why a bottleneck keeps happening, or just the overall activity looks like in the warehouse.

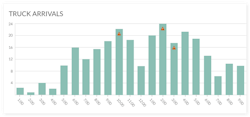

For example, if there is a huge spike in dock delays at 3 p.m., the supervisor can examine the whole picture and discover an excessive number of trucks arrived during that time, and the schedule needs to be adjusted so that it doesn’t happen again.

Conversely, new opportunities for continuous improvement can be gleaned from looking at docks with lower dwell times to repeat that success.

Prior to solutions such as SmartDock, Davidson said there was “No defined way to measure these without sending out with clipboard.”

The cameras themselves operate for multiple years on AA batteries and the system has an open API architecture, meaning companies can synch up their warehouse management system for broader visibility. Someday, autonomous mobile robots may even get the alerts directly to speed up the loading of a truck to minimize detention time even more—though there is no time table on that.

The SmartDock allows any transportation facility, big or small, to leverage the same type of technology Amazon employs to shave precious minutes from its loading and unloading time, Davidson said, though for now the new technology launched last year makes the most sense for medium-sized companies and above.

“Any warehouse that has that has drivers sitting around waiting and racking up detention fees, that’s where we can provide a lot of benefits,” he said.

The wider waiting problem

The issue is far larger than keeping one driver from growing impatient. It’s a systemic problem.

It’s standard practice for the carrier to allow a two-hour window where the customer does not get penalized for keeping the driver in limbo. It’s also typical that this driver does not receive any compensation during this grace period. They do receive a portion of the detention fee, though an American Transportation Research Institute study reported only 29.3% of carriers recoup all their billed fees. The ATRI also found detention time increased from 2014 to 2018.

Because drivers get paid by the mile, and their drive time gets further whittled down to comply with the ELD mandate, patience appears to take a backseat to their livelihood. According to the Office of the Inspector General (DOT), when dwell time increases by 15 minutes, the chance that truck will be involved in a crash rises by 6.2%. The cost to drivers can reach more than $1,500 annually, and the trucking industry’s net loss is $1.35 to 1.6 billion.

Help is unlikely to come from the government.

According to an official, the Federal Motor Carrier Safety Administration “primarily views detention as a market efficiency problem best addressed by private industry rather than through government action.”

This makes it all the more likely technology such as SmartDock will see a growing demand.

“It’s a matter of fairness,” said Don Thornton, a senior vice president at DAT Solutions about detention time. “Many shippers and receivers are lax about their dock operations, but it’s the carriers and drivers who are forced to pay for that inefficiency.”

Carriers are starting to take their own action, simply not doing business with customers apathetic to truckers’ time. Since the ELD mandate has been in place, Zipline Logisitics reported 43% of carriers state that the number of shipper/receivers they refuse to go to has increased.

“It doesn’t really matter how many free snacks or how many free Diet Cokes you have,” Zipline president Andrew Lynch told Business Insider. “If you’re taking up four hours of a driver’s time, you’re ruining their day. And no amount of free pretzels can make that up. It all comes down to ensuring detention time is kept to a minimum.”

About the Author

John Hitch

Editor

John Hitch is the editor-in-chief of Fleet Maintenance, providing maintenance management and technicians with the the latest information on the tools and strategies to keep their fleets' commercial vehicles moving. He is based out of Cleveland, Ohio, and was previously senior editor for FleetOwner. He previously wrote about manufacturing and advanced technology for IndustryWeek and New Equipment Digest.