‘Stable’ medium-duty market shows positive signs for mid-decade growth

The medium-duty commercial vehicle market is “struggling to find its way,” according to Steve Tam, VP at ACT Research. “It’s just moving sideways at this point. There’s very little variation—even historically in the marketplace. But looking forward over the next five years in our forecast, you can’t see a lot of movement in this marketplace. It tends to be a pretty stable affair.”

Like so many other segments of commercial vehicle equipment, the supply chain is driving the medium-duty market. “This cycle is not all about demand—it’s all been about the ability to fulfill that demand,” Tam said during ACT Research’s Seminar 67 in Columbus, Indiana, in late August. “For that reason, I think we made progress on that front—and that’s a positive for this industry and this space.”

See also: Equipment supply chain poised to meet pent-up fleet demand in 2023

With a looming recession that ACT Research expects to be “shallow and short,” Tam said he envisions medium-duty demand to remain steady into 2023. That ACT 2022 medium-duty production forecast (Classes 4-7) is 254,000, of which 205,000 are trucks. That number jumps to 271,000 MD units in 2023 (219,000 trucks). In 2024, ACT forecasts 277,000 MDs (219,000 trucks). In 2025, the forecast reaches 300,000 MDs (238,000 trucks) before peaking at 328,000 MDs (262,000 trucks) in 2026.

“So not a bad place to be,” Tam said of the medium-duty production outlook, which tops the average replacement statistics of 240,000 per year. “Now, we’re paying for previous sins because we under-replaced in 2021,” he said. “So the age of fleets increased—and arguably shrunk a bit—so we’ve got to fill that back in, which is kind of the theme of the forecast.”

Medium-duty market caught in middle of light and heavy demand

Class 4 made up 10% of the U.S. medium-duty market sales year-to-date. It started 2022 on par with previous years, but Tam said the MD market slowed with inflation in late spring. “The demand for that type of vehicle seems to be slowing down a bit,” he said.

Class 5 has made up 35% of the U.S. MD market through July this year. After a strong showing in Q1, “it kind of got its knees knocked out from under it” in April,” Tam said.

The Classes 6-7 market makes up the other 55% of the MD market. “It had a normal start to the year that has just kind of skyrocketed and stayed elevated,” Tam said of its performance through July. He credited this to the rental and leasing market, which relies on the larger medium-duty box trucks that had “a really lumpy replacement cycle over the last four or five years.”

See also: Look back at 75 years of Ford F-Series trucks

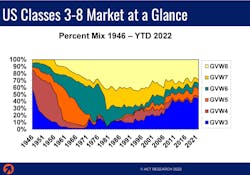

One of the medium-duty market’s biggest obstacles is the growing heavy-duty appetite of commercial fleets. “Class 8 is gaining share on Classes 3 through 8,” he said of the entire CV market. “In fact, they’re gaining almost 300 basis points, year-to-date. You can see the loss is kind of split almost equally by Class 3 and in Classes 4 through 7.”

He added: “And that phenomenon, I believe, is not taking place only at the light-duty end, but also among the traditional entrenched manufacturers who make heavy trucks and medium trucks. So they’re diverting resources away from those mediums in favor of the heavies. You see it in the data. I don’t know how to refute it. But I think that is why we’re not seeing as much love in the medium-duty space these days as we typically see.”

Upfitting pipeline is longer

But Tam later said that the underlying fundamentals—pent-up demand, trade cycles, populations, average ages—for MD vehicles are likely to be fulfilled eventually. But one thing holding back the inventory-to-retail sales ratio is supply.

“I think the best explanation here is that we’re just having a heck of a time getting the trucks or chassis from the factory to the customer,” Tam explained. “They’ve got that stop in the middle where they have to go to that body builder. Unfortunately, the body builders and the upfitters are living in the same world we are in the chassis world, in that they’ve got supply chain constraints as well. They’ve got labor issues. So that pipeline is just taking longer. And that’s what’s accumulating inventory. There are not many chassis sitting on dealers’ lots waiting for people to come and buy them. That influx of inventory is not units available for sale—it’s units working their way through the pipeline.”

About the Author

Josh Fisher

Editor-in-Chief

Editor-in-Chief Josh Fisher has been with FleetOwner since 2017. He covers everything from modern fleet management to operational efficiency, artificial intelligence, autonomous trucking, alternative fuels and powertrains, regulations, and emerging transportation technology. Based in Maryland, he writes the Lane Shift Ahead column about the changing North American transportation landscape.