Eaton releases paper on role clutches play in reducing vibrations

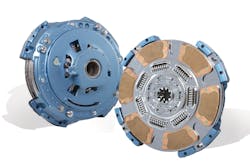

Mechanical clutches can play a role in protecting drivetrain components from torsional vibrations in commercial trucks, said Eaton Corp. The company has now published a technical paper, titled “The Role of Mechanical Clutches in Dampening Torsional Vibrations,” explaining how modern damper technology can help.

The one-page, two-sided, color document (item number CLWP0001) is available at www.eaton.com/roadranger, the online site for all sales and service support for Eaton’s commercial vehicle operations in North America.

The paper also points out how modern dampers have been adapted to work especially well with today’s high-torque, low-speed engines, which increase the amount of vibration in the drivetrain.

“The damper is the most critical part of a clutch. If you design the stiffness of the damper appropriately, it will positively impact the entire driveline,” said Prashant Kulkarni, engineering manager – clutch division, and author of the paper.

The paper includes information on how breadth of product, selecting the correct amount of friction material and the number of springs all factor into the success of a modern heavy-duty clutch. Kulkarni also presents an informative overview on how clutches have evolved over the years.