Engine oil technology has improved enormously in the last decade, and current blends work harder and protect vehicles better. Plus, with the right oil, fleets can extend oil drain intervals and travel further between scheduled maintenance, helping to improve productivity, reduce oil waste and generate savings.

Engine oil has multiple responsibilities, including reducing friction, transferring heat away from the engine's moving parts, and removing or neutralizing impurities and foreign particles that would otherwise clog filters, piston rings and other vital components. Two things determine the quality of engine oil or any other lubricant—the quality of the base oil and the additives used to enhance the protection offered by the engine oil.

“Choosing a better synthetic base stock gives you some enhanced antioxidant protection and, in some cases, better durability,” said Dr. Jason R. Brown, global technology manager for heavy-duty engine oils for Shell.

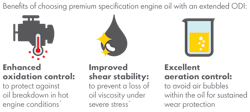

Changes to the refinement process have improved base oil quality and can make the oils more resistant to high engine temperatures. Using more and improved antioxidants also provides additional engine protection against oil breakdown in hot and/or severe engine conditions.

“Putting in the right high-quality ingredients will get you a better product in the end. If we do it right, we can design an oil that can do more and do more for longer,” Brown said.

Even though there is a slight cost increase when moving from conventional to semi-synthetics and synthetics, there is often a long-term benefit due to the lower number of oil changes needed and increased up time. Brown said that using a higher-quality oil with better protection could also impact resale value. “If we keep the vehicle running better longer, there could be a benefit on the resale side,” he said.

Oil Drain Intervals

Like any other consumable, engine oil has a useful lifespan. After being in the engine for a while, the heat and stress oil has been working under reduce its lubricating properties. It also becomes contaminated with particulates, soot, and other substances—making it less effective—and it must be drained and replaced with fresh oil.

Often, the oil drain tends to get done when the truck goes in for its service but draining oil that has months or thousands of miles left in it results in increased waste and expense. Ultimately, the maximum amount of time between oil drains depends on the specification of the engine oil used, the manufacturer’s guidelines for the truck’s engine, and the truck’s operating conditions. “The OEMs set oil drains because they have the biggest liability and warranty on the vehicle. They make decisions on oil drain intervals in a manner so they can still protect the equipment,” Brown said.

While OEMs set oil drain intervals, oil marketers—including Shell—can help fleets get approved extensions. As part of the process, Shell conducts oil engine analysis and collects data to validate extended ODIs. “We can support the customer in speaking to the OEM about those extensions, and we have done that with customers before,” Brown said.

Sometimes fleets are even able to go longer with what they already have once they have a better understanding of ODIs, Brown said. “There may already be a benefit that customers aren’t getting their hands on. Our main goal is to help our customers get the most out of their vehicle and the most out of their oil,” Brown said.

Factors that could lead to an earlier oil change include extreme hot and dusty environments, heavy vehicle loads or long idle times. OEM guidelines provide recommendations for light, medium and heavy-load duty cycles.

Long-haul applications that use an engine oil that meets the API CK-4 specification with a Detroit Diesel DD15 engine should change the oil every 60,000 miles, according to the owner’s manual. If it is left longer, performance may suffer, and the oil may not be protecting the engine well enough. It could even void the warranty.

Synthetic engine oils may work better in harsh environments. For example, the Shell Rotella T5 Synthetic Blend 10W-30, which has better cold-cranking properties and low-temperature pumpability at -13˚F and -22˚F (-25˚C and -30˚C), respectively. It reaches critical engine parts faster in cold temperatures, minimizing engine wear and making hard work easier in harsh environments.

The Value of Engine Oil Analysis

While changing oil too early means fleets may be spending more money than necessary on engine oil, leaving oil in too long may result in vehicle damage. Engine oil analysis can help fleets pinpoint the best time to change oil by recommending oil drain interval extensions and detecting lubricant conditions before major issues occur. Plus, fleets can use the data to monitor equipment’s performance and inform better maintenance decisions.

Shell LubeAnalyst draws on 30 years of oil condition monitoring experience to help maximize equipment life and reduce maintenance costs. “If I’m able to follow the performance of the engine and the oil with some degree of regularity, I would allow the oil condition to tell me when to change it,” Brown said. “Maybe the ODI is 55,000 miles but because of your application, you could get 70,000 miles. With condition-based monitoring, we’d be following the performance over that time and could make a clear determination.”

As part of the process, fleets send samples to Shell’s network of approved labs or use on-site diagnostic equipment. Fleets don’t have to test the entire fleet but instead can get a statistically valid sample based on trucks’ service and application. They can then repeat tests based on how often and how many trucks turn over. “Once we get to where we think we need to be and have approval from the OEM, then we just monitor from then on,” Brown said.

The Oil Selection Process

Several resources are available to help fleets ensure they're getting extra protection by using the correct oil specification for their operating environment, equipment application and engine needs. Visit Shell LubeMatch or contact your Shell Rotella distributor.