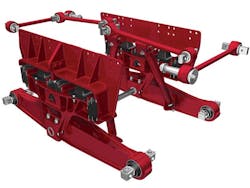

Hendrickson suspension option for Kenworth T880

INDIANAPOLIS. Kenworth Truck Co. announced availability of the Hendrickson UltiMaax suspension on its T880 at this week’s NTEA Work Truck Show.

The UltiMaax is an advanced severe-duty rubber suspension that offers a balance of empty ride quality and loaded stability for driver comfort, while also cushioning the load and protecting the chassis, cargo and body equipment from excessive vibration and road shock due to potholes and rugged terrain, Kenworth said.The suspension is available with axle ratings from 46,000 to 52,000 lbs., axle spacings of 54- and 60-in. with 11-in. ride height for applications such as refuse, sand and gravel, crane/boom, platform, construction, and logging.“Fleets that operate trucks up to 52,000-lb. capacities can now specify the Hendrickson UltiMaax severe-duty suspension with the Kenworth T880 to provide their drivers with a consistently smooth ride while running loaded or empty on the harshest roads and terrains,” said Kurt Swihart, Kenworth marketing director. “The Kenworth T880 equipped with a Paccar MX-13 engine rated up to 500 hp. and 1,850 lbs.-ft. of torque already provides a durable, reliable and productive vocational truck for such demanding applications. The severe-duty suspension helps enhance the T880’s traction, stability and handling under loads from 46,000 to 52,000 lbs.. Plus, it adds even more durability and helps customers maintain a lower cost of operation with its components designed for maximum weight savings for additional payload.”