Drōv develops 'smart' trailer technology, partners with Stoughton

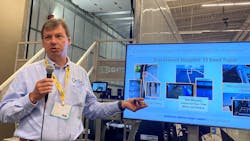

CLEVELAND, Ohio—Over the last four years, Drōv Technologies has been working on integrating “smart” components and sensors into the commercial trailer through it’s AirBoxOne platform. Now, the technology provider has just announced a partnership with Stoughton Trailers during the American Trucking Associations’ Technology & Maintenance Council’s 2021 Fall Meeting.

“We saw on the truck side there was so much innovation and so much consideration for technology. What we noticed was that very little of that was happening on the trailer side,” noted Lisa Mullen, Drōv CEO, during a TMC press conference.

“Without making the trailer safer today for the driver, there was little chance that autonomous transportation would be successful,” she added.

According to Drōv CTO Pete Jankowski, AirBoxOne can read any sensor on the trailer; check, change, and control tire pressure electronically; monitor wheel ends, the vibration of the hubs, and temperature; track the weight of the vehicle through the axles; and read ABS faults. The platform also connects to cargo and rearview cameras, ultrasonic backup sensors, and additional sensor integrations to detect wheel-end temperature and load weight to extreme G-forces and cargo security breaches.

On the front nose of the trailer, fleets can press a button and access the health of the asset. On the wheel ends, Bluetooth sensors recognize vibration on the hub, so if temperatures get hot or if there is a vibration from loose lug nuts or bearings, fleets and drivers will receive a warning. Inside the trailer is a cargo camera that can take pictures when the door opens and closes to help fleets monitor loading and unloading.

“The camera in the back will record video for a few weeks, so if something happens, you can go back and look at the backup camera footage,” Jankowski said. “We are also putting cameras on tankers [to track] loading and offloading for safety.”

AirBoxOne primarily runs on auxiliary power and has a backup battery and solar charging, Jankowski noted. Redundancies are built into the system to ensure that the power sources always function, he added.

Overall, system costs depend on features added, Jankowski explained. He pointed out that return on investment is roughly 12 to 18 months based on savings from fewer roadside breakdowns and service stops.

About the Author

Cristina Commendatore

Cristina Commendatore is a past FleetOwner editor-in-chief. She wrote for the publication from 2015 to 2023.