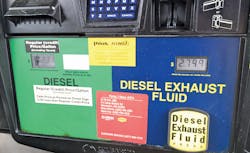

The American Petroleum Institute (API) recently issued a bulletin stressing the importance of only using certified diesel exhaust fluid (DEF) for the diesel-powered vehicles that require the fluid.

“Truck drivers and fleets can find quality brands of DEF through a real-time directory which lists API-licensed products that meet diesel engine manufacturer recommendations. This ensures that diesel engine warranties are protected and helps protect the overall investment in the truck,” API said.

The group oversees a voluntary certification program that monitors the characteristics of DEF, as well as quality through an aftermarket audit program.

“DEF is made from a 32.5 percent solution of technically pure urea with the rest of the mixture consisting of purified water,” API said. “For the SCR unit to operate properly, the DEF must meet an exacting purity standard established by the International Organization for Standardization (ISO). This ensures that the DEF provides the purity required by diesel engine manufacturers and the quality to preserve the emissions control system and the environment.”

The use of DEF is needed for trucks using selective catalytic reduction technology to meet Environmental Protection Agency diesel exhaust emissions standards.

Back in a 2009 Q&A report, Cummins Filtration explained how DEF works: “Small quantities of diesel exhaust fluid are injected into the exhaust upstream of a catalyst, where it vaporizes and decomposes to form ammonia and carbon dioxide. The ammonia (NH3) is the desired product which in conjunction to the SCR catalyst, converts the NOx to harmless nitrogen (N2) and water (H2O).”

In the same document, they cautioned would-be do-it-yourselfers to be very careful about the purity of the DEF they used: “DEF has strict requirements for maintaining concentration and purity of ingredients that is critical to the proper functioning and longevity of the SCR system.

About the Author

Wendy Leavitt

Wendy Leavitt is a former FleetOwner editor who wrote for the publication from 1998 to 2021.