True North expands cold storage

True North Logistics (TNL), headquartered in Downers Grove, Ill., recently made an additional 40,000 square feet of refrigerated warehouse space available at its refurbished warehouse in the Southeastern United States.

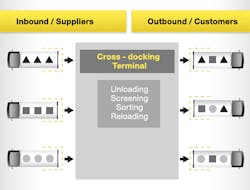

The company said it also now provides cross docking and complete warehouse support services. The TNL cross-docking practice is a logistics management service that includes unloading incoming delivery vehicles and loading the materials directly into outbound delivery vehicles, omitting traditional warehouse logistical practices and saving time and money.

Our on-site receiving team process incorporates lessons learned and best practices, including:

- Establish minimal flow path: Ensuring that for each product coming from each type of supplier that our team has selected and established the minimum cost flow path

- Minimize delay: Confirming there is no delay between the receiving process and the warehousing process

- Assign receiving docks: Assigning a planned product location while the item is in transit. Securing the exact location for all inbound items and pallets that will be received in the warehouse. Assign each inbound truck to the dock door that minimizes the processing time for that inbound truck.

TNL’s available warehouse includes more than 40,000 square feet of chilled warehouse space, as well as additional ambient temperature space upon request.

Visit truenorthlogistics.com for more information.