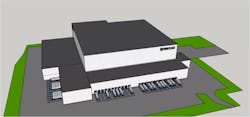

NewCold’s new deep-freeze facility nears completion

Automated cold storage specialist NewCold says Europe’s largest new deep-freeze facility, located on former steelworks land in Corby, England, is “months away” from completion.

Work on the development, which will help NewCold meet growing demand from the food manufacturing sector, began in late 2020.

“The company already has a strong demand for its services at its Wakefield site and sees Corby as a prime location in the logistics ‘golden triangle,’ with proximity to frozen distribution centers of large retail and food service customers,” said Ross Hunter, NewCold’s supply chain director. “This will enable NewCold to help our customers reduce food miles and cut costs.”

When fully operational, the site will employ more than 250 people, but automation will play a key role in the facility’s operation. NewCold, headquartered in the Netherlands, operates from 14 locations on three continents.

“Since opening our first U.K. site in Wakefield seven years ago, we have seen an increase in demand for our warehouse and transport services and although the Wakefield facility is the largest of its kind in the country, handling 4 million pallets annually and storing 143,000 at any given time, demand has outstripped supply,” Hunter said.

That demand led to NewCold deciding to establish another facility further south in the U.K., the company said, creating additional benefits for frozen food manufacturers and importers.

The Corby operation will enable NewCold to offer its services to customers for whom Wakefield isn’t geographically well-situated, or who have run out of space.

NewCold adds that it is in talks with “high-volume potential customers” who are associated with global brands. Each of them will benefit from NewCold’s sustainable transport, storage, and WMS solutions, including automatic handling equipment to reduce loading times, while retaining product integrity.

“The decision to build a second facility has been driven by an increasing wide-scale demand for storage and handling, while the number of deep-frozen storage facilities has reduced,” Hunter concluded. “This has seen cold stores at capacity during certain times over the last two years and the trend appears to be continuing, so we feel this is the right time to invest.”