Trackers vs. loggers: Which are right for your operation?

Key Highlights

- Trackers provide real-time data on temperature, location, and shocks, ideal for high-value shipments and theft prevention, while loggers are passive devices suited for routine compliance checks.

- Key decision factors include shipment risk, data access needs, real-time visibility, geographic scope, supply chain complexity, and customer or retail requirements.

- Hybrid or multi-device approaches offer granular visibility, helping mitigate risks, reduce waste, and streamline operations across complex, multi-stop, or international shipments.

- Long-term benefits of cold chain monitoring include improved compliance, vendor accountability, trend analysis, labor savings, and enhanced product safety.

- Partnering with experienced, global providers ensures reliable technology, seamless integration, and ongoing support to maximize the advantages of cold chain visibility.

Cold chain logistics and management is a case study in high stakes.

Risks like costly load rejections, increased theft, evolving compliance requirements and supply chain complexity affect the bottom line for every stakeholder, not just the outbound or inbound players.

The best way to mitigate these risks is through transparency and solid decision-making, which is why cold chain visibility is no longer optional but a critical requirement.

So how do you pick the right cold chain monitoring solution provider? After all, there is no one-size-fits-all option. Start with the basics: the differences between trackers and loggers, key decision factors, and when a hybrid or multi-device approach makes sense. Pairing that knowledge with your needs and responsibilities will help you mitigate risks, leverage data effectively, and build trust with your cold chain partners.

What’s the difference between a tracker and a logger?

Trackers and loggers are both recording devices, but they differ in functionality and use cases.

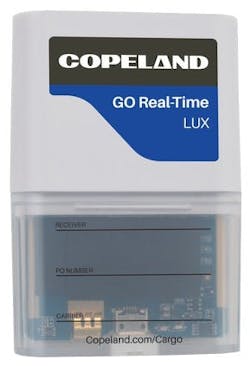

Trackers actively record in real time, transmitting data via cloud. They record temperature, GPS/location, humidity, motion, light, and shock. Trackers are ideal for real-time visibility, security, and proactive issue response.

Loggers use passive recording—data retrieved upon arrival or at stops and accessed via USB, NFC, RF, or proprietary handhelds. They typically capture time and air temperature, with the option for humidity and probe (internal temperature) data. Loggers are well-suited for routine compliance or delivery quality checks.

How to decide between using a tracker and a logger

Supply chains are becoming increasingly complex, but choosing between a tracker and a logger is relatively easy. And the benefits of monitoring extend to every stakeholder, not just the producer or receiver.

Shipment value and risk

The cost difference relative to the value of a given shipment is minimal, so that’s not the subject of this factor. The more important issue is protecting high-value or high-risk commodities.

If, for example, you’re shipping a seafood product that’s highly susceptible to compromised quality and freshness, then in the event of a temperature breach, you may want more data granularity. That way there’s no possibility of unaddressed micro-pockets of hot air inside a trailer. Some of the product might be shipped to spec, but the rest could harm the consumer. Being able to partially reject a load minimizes claims associated to the shipper, carrier or whoever else is involved in the process.

The solution: Trackers or a hybrid, multi-device approach (more on the latter below).

Data access and ease of data extraction

Who can access the data is just as important as the ability to collect the data.

Let’s say you’re delivering a multi-stop shipment to three different grocery competitors. If you need to block public access so that end receivers can’t download data without your permission, but you still want them to be able to access their data without repeated access requests, a tracker makes the most sense.

For shippers that bear the responsibility of transportation and cooling but don’t have control of the end destination, it’s important to have access to information that can be shared with other stakeholders like the transport provider and end receiver (retailer/importer). In this scenario, a tracker also works best.

Your monitoring solution should allow you to gatekeep data as necessary while effortlessly providing you with the data you need as soon as possible, if not immediately.

The solution: Trackers, with exceptions for simpler, logger-appropriate scenarios.

Real-time visibility needs

Do you need to estimate the arrival time of trucks at your distribution center? When loading docks are in short supply, arrival windows can make all the difference in effective scheduling. Are you concerned about theft and want to know about route deviations or other abnormalities as soon as they happen? You’ll need real-time updates, not wishful thinking from the last-reported shipment location.

Deliveries requiring predictive ETAs for scheduling and resourcing require the active monitoring that trackers provide.

The solution: Tracker.

Geographic scope and infrastructure

Maybe your primary concern is tracking sea container shipments without cell tower access, where incidents are more likely before and after but not during oceanic transit. Maybe you’re responsible for international shipments requiring location and status updates that can be downloaded automatically. With a traditional passive logger, you can easily cover the first scenario, but for anything requiring real-time updates, especially those with ownership and logistics provider changes, trackers are your best monitoring bet.

The solution: Logger for pre- and post-delivery data only, trackers for real-time updates.

Supply chain complexity

The last thing you want to add to an already complex supply chain is more complexity. With a passive logger, you must request data from the receiver or retrieve the logger to get the data for review to determine what happened, how and for how long.

For multi-stop, multi-pick or international shipments, except in the most straightforward of cases, a tracker makes the most sense. Trackers will provide insights about consistency, quality, and safety-related issues to all stakeholders.

The solution: Trackers, except where cost-efficiency is paramount.

Retail/customer requirements

A retailer might mandate that all their suppliers use a temperature logger because they want a single, consistent way of digesting their information. Even though a tracker can provide them with more information, it won’t be the same type or in the same format or style that they could get from other vendors. So, the shipper may elect to place a logger on a trailer to be compliant with that customer’s needs. If the shipper also wants to access the data and prevent claims before they can happen, they could use a real-time tracker as well.

Whatever your customer requirements, consider your own as well so your solution covers everyone’s interests.

The solution: Varies; potentially a hybrid approach.

Integration needs with ERP/P.O. systems

Data ownership plays a big role in effective cold chain monitoring. Sometimes a load is owned by the person who picks it up from the facility. Sometimes payment is made after delivery, depending on quality and consistency. Monitoring ensures that everyone gets paid for their work.

Think about your needs for API availability and compatibility with P.O./shipping systems. Do you, for example, need to connect a P.O. number with a specific serial number from the supplier and combine that data before upload to your own database (and/or an end-user’s)? For two-way data flow, you’ll need a tracker that’s integrated with whatever application you’re using. Your monitoring provider should offer seamless integration (more on what to look for in a provider below).

The solution: Varies; potentially a hybrid approach.

To sum up, trackers are ideal for high-value or high-risk shipments (e.g., seafood, pharmaceuticals, cherries), international shipments where location and status updates are crucial, deliveries requiring predictive ETAs for scheduling, and situations where theft detection or customs delay identification is needed. Loggers have their place with shipments where simplicity and cost are key, in situations with the infrastructure for automatic data download, and for the sake of standard retail compliance (e.g., arriving at distribution centers).

Using trackers and loggers together: hybrid or multi-device approaches

A single device is simpler and costs less. But low-risk, uniform cargo probably isn’t your norm. There’s no sense in sticking with one option if it doesn’t meet your needs or sufficiently mitigate the risk of liability. In those cases, using both a tracker and logger, or multiples of each, is a wise decision.

You might need to use a tracker for real-time monitoring and a logger for retailer compliance or backup (e.g., one real-time tracker plus a logger per pallet for granular temperature logging).

For multi-pick/multi-drop, P.O.-level traceability or microclimate detection, using multiple devices will give you more granular visibility, simplified loss compensation resolutions and protect the safety and integrity of temperature-sensitive products.

Remember the overall cost of not protecting your shipments. In light of that, layered monitoring through a hybrid or multi-device approach is a small price to pay.

The long-term benefits of cold chain monitoring

Cold chain monitoring devices are clearly not just applicable to one-offs. They help reduce waste, aid in theft detection, simplify resourcing and reduce drawn-out loss claims in the short term.

Copeland also advocates for the long-term benefits of loggers and trackers: They provide the data analytics to track compliance, establish logistics and carrier accountability, assess trends (e.g., vendor/carrier performance, seasonal temperature shifts), simplify and streamline the receipt process, save labor hours and reduce overall labor spend, and take prescriptive action.

While choosing the right monitors or monitor combination is critical, so is choosing a reliable monitor provider. Keep your best interests, your brand and your quality in mind with a proven global provider that meets the following requirements:

- Deep experience in your vertical, with a proven track record of quality and consistency and a long list of customers. This ensures they can give you actionable insights into industry data and trends.

- A global provider of cold chain monitoring technology (e.g., Copeland provides data access/user interfaces in multiple languages, support around the world and around the clock).

- A one-stop shop that can help you with any cold-chain need.

After all, the best way to take advantage of the myriad short- and long-term benefits that cold chain monitoring has to offer is to partner with someone worthy of your long-term trust.

About the Author

Gerd Uitdewilligen

As director of international sales at Copeland, Gerd Uitdewilligen lends his expertise and insights into perishable shipment visibility throughout the cold chain. With over a 19-year tenure in the produce technology industry, his influential presence is felt as an active member of the global cold chain technology industry and attending industry events around the globe.