TI Cold introduces QFM mobile in-rack freezing system

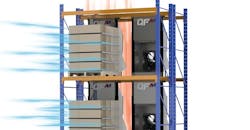

Tippmann Innovation (TI) recently released the QFM mobile in-rack freezing system, which the company says is the next evolution of QuickFreeze, adding flexibility, remote control, and new ways to manage blast freeze and tempering demand.

Over the last 10 years, QuickFreeze replaced blast cells in new construction and retrofit of food production facilities and PRWs, TI said. The modular design of QFM improves upon the performance of QuickFreeze, allowing operators to install and remove units from their facility in as little as 10 minutes per pallet position. Operating on 3-Phase power, the QFM units ‘daisy-chain’ together, using less than 1 amp per unit. If blast freeze is seasonal or the location for blast freezing changes, QFM is ready to follow demand.

“QFM assures exceptional and precisely delivered airflow to every pallet, along with state-of-the-art controls, monitoring and flexibility,” said Dan Tippmann, partner at Tippmann Engineering. “These features provide users with a significant freezing/tempering advantage they can showcase to their customers.”

Each QFM includes a control board, which connects to the cloud wirelessly through existing facility WiFi. This allows the user to remotely monitor and control each unit, while important KPI data is pushed to the cloud.

Blast Freeze requirements for protein export have been changing in the last 3 years, and QFM allows operators to meet the new requirements quickly, TI said.

QFM is simple to operate. When a palle Colt is placed in front of the unit, the QFM is designed to automatically turn on and run until the dwell timer expires. If the pallet is removed before the timer expires, the unit also turns off.

The dwell timer can be set remotely by manual user settings or programmatically by the operator’s WMS (Warehouse Management System). This allows the operator to define the dwell time by the SKU of the product.

TI said QFM underwent extensive field testing over the last year in refrigerated warehouses around the country.

Learn more about QFM and how it can improve and expand blast capabilities at ticold.com/qfm.