SAF-Holland TRAKr e-axle coming to N.A. market for reefer applications

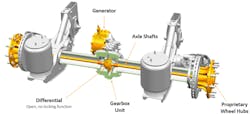

ORLANDO, Florida—SAF-Holland has announced the TRAKr e-axle for trailers will be arriving at North American fleets by the end of 2022. The recuperative axle technology converts the rotational energy from an internal driveshaft within the axle, through gear reduction, by way of a generator mounted to the gearbox unit.

That energy is stored in a lithium-ion battery system on the trailer, which then provides power for auxiliary devices such as a trailer refrigeration unit. Transportation refrigeration units (TRUs) traditionally rely on diesel fuel, which create emissions and noise that cities are trying to eliminate via ordinances. The TRAKr electric trailer axle can provide an alternate source of power generation that is greener, quieter, and more efficient, SAF-Holland said.

“SAF-Holland's mission is to take the leadership role in the transformation of mobility and to partner with our customers on the road to the sustainable future,” said Thomas Piroth, VP of global digital and innovation, SAF-Holland, at American Trucking Associations’ Technology & Maintenance Council 2022 Annual Meeting & Transportation Technology Exhibition.

Piroth emphasized the trends sweeping the commercial vehicle space: highly automated driving, digitization, connectivity, and electrification. He also mentioned the zero emission zones in places such as Amsterdam, which will compel fleets to develop more electrification solutions.

“Our e-axles are developed to reduce noise, to reduce CO2 … and to meet stricter regulations of the future," he explained.

The company wants to meet the trend head-on in the North American market, though that will take some additional development and testing for the U.S. and Canadian duty cycles.

“The first thing we need to do is integrate into our North American axle and suspension range, which is different from the European axle and suspension range,” explained Mike Ginocchio, VP of engineering—Americas, SAF-Holland. He also stated that integration is just the first step, as this product must be validated and then go through all of the testing phases—including in the lab, on the track, and in the field—to ensure performance and reliability.

Furthermore, the integration process will rely heavily on partnerships with key technology providers, Ginocchio explained.

“We have a look at the unique North American requirements for the TRAKr system as well,” he said. “Our speeds, our loads, our duty cycles are quite different from the European market. The applications: long haul, short haul, whether it’s a cycle TRU or a continuously running TRU, is it just cool or is it freeze?” This wide range of variances will dictate how the company integrates the TRAKr system into the N.A. market, as well as where the emphasis of integration will begin.

High-voltage maintenance

As with any new e-system in the CV industry, questions arise surrounding the maintenance of battery-electric systems and the handling of high voltages.

“A big part of this, in addition to the mechanical side of connecting into our axle and suspension, is getting the power [that is] starting to generate [within and then] leave that TRAKr system in the middle of the axles because on the electrical side there are some very, very high voltages happening here,” Ginocchio stated. “The generator generates up to 600 volts. And we will supply that voltage to a battery, which will then invert it to DC power which can still generate 300 to 400 volts, and send that to the refrigeration unit or TRU.

“We have to be really careful with this,” he continued. “Safety is of the utmost importance in our test labs, in our manufacturing plants, and then when it leaves there, with our customers. We need to be very careful and thorough with our OEM and customer training, our fleet training, maintenance training—every area that the market touches.”

With safety a priority, SAF-Holland designed the TRAKr system accordingly. Ginnochio stated that for trailer axle maintenance, whether it be wheel end maintenance, hub maintenance, or else, technicians would not be getting into or near the power supply. That is because the power supply and electrical activity is within the middle of the axle.

Beyond electric-related maintenance concerns, Bill Hicks, product manager, trailer axle/suspension systems—Americas, SAF-Holland, stated that the normal system maintenance will not be impacted.

“We want to make it service-friendly,” he said. “Wear parts, brake pads, all that stuff would not change. That is very important for fleets.”

N.A. integration

According to SAF-Holland, the modular system is configured for ideal integration, resulting in maximized system efficiency. Trailer OEMs should find them easy to install using standard assembly line procedures. The TRAKr e-axle will be available on both SAF mechanical and air suspension tandem axle slider systems for reefer trailer applications.

Hicks explained the TRAKr system will look different in North America.

“The hub will be basically a North American standard," Hicks said. "It’ll fit with all the tires and rims, but it will have a drive axle or an axle shaft [going] into the gearbox, which will generate the electricity.”

The axle shaft coming from the hub will lead into the differential. Rotational energy will be going into the gearbox, driving the electrical generator. What is unique, Hicks said, is that the axle driveshafts are inside the axles, where normally a trailer axle is hollow.

SAF-Holland plans to collaborate with partners as part of a three-part system for a total solution for the trailer, the fleet, and the trailer OEM. Part one being the trailer OEM integrating the TRAKr system, part two being collaboration with battery suppliers, and part three are the TRU manufacturers.

“Of course, number one is our TRAKr e-axle,” Hicks said. “Typically in North America, you’re running tandems. The first axle would have the TRAKr system. It will generate the electricity, but this would go into the battery pack. The battery pack controls the state of charge and the energy distribution. Also with the battery pack, there would be an auxiliary shore power if it were parked.”

The EV market has a litany of available avenues to pursue emission reduction and electric integration. SAF-Holland's TRAKr system, Hicks said, can work as a better solution than a full electric tractor and trailer combination sharing a single battery pack.

“We believe our solution with the recuperative axle is a better solution,” Hicks surmised. “If you’re going down the road, it would generate and keep the state of charge. You can maintain it while you’re running anywhere from New York to California, and you really wouldn’t have to worry about it.”

Hicks mentioned the concerns of range for full electric tractors and warned that sharing that power load between tractor and trailer could further lead to cause for concern with range anxiety. This is voided with TRAKr.

“We will have greater flexibility because we’re charging the battery pack while we’re driving down the road,” he said. “You literally would not have to stop going from across the country for a charge. It gives you greater range and flexibility. That’s important. Obviously, with this system, we do not need as large of a battery pack, which is a big deal when it comes to the weight, the weight of the battery pack on the trailer as well as the cost factor.”

Beyond range and weight benefits, Hicks highlighted the noise reduction benefits that the TRAKr system would deliver versus a diesel-powered TRU. Re-emphasized by Piroth, noise reduction zones are already established and widespread—so preparing for emission reduction or emission free zones is one thing, but being compliant in noise reduction zones is immediately impactful.

The target market applications are reefers, Hicks concluded. Although, he reinforced that the TRAKr system is for climate control trailers, not just cooling but heating as well. SAF-Holland expects to have prototypes operating in North America by the end of the year, collecting data and leading the development process.

About the Author

Tyler Fussner

Assistant Editor | Vehicle Repair Group

Tyler Fussner is a former assistant editor for Endeavor Business Media's Commercial Vehicle Group, including FleetOwner and Fleet Maintenance.