Scientist-activists call for 40% improvement in truck fuel economy

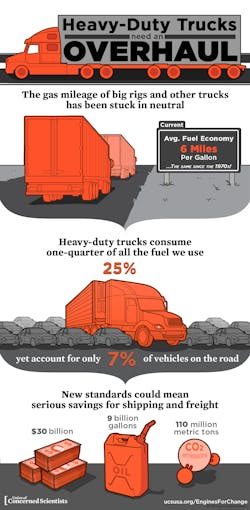

Citing “years of non-regulation and slow investment,” the Union of Concerned Scientists has called for “strong federal standards” for heavy-duty truck fuel economy, with a goal of cutting fuel consumption by at least 40%.

The push, dubbed “Engines for Change,” was launched Wednesday and focuses on a 24-page report which details the amount of fuel used by trucks to move freight and specifically to haul consumer goods, along with the savings that would be generated for both consumers and truckers by developing more fuel efficient vehicles.

“The technology to do this is within reach, and can be deployed cost effectively,” said author Dave Cooke, vehicles analyst at UCS, speaking to trucking industry media. “Because so much of what we buy comes on trucks, fuel for shipping is included in the cost of nearly every product. That is money consumers are paying to maintain the status quo. We know we can do better.”

The report recognizes that fuel savings are very important to commercial fleets, but insists that “a key reason” truck fuel economy hasn’t improved since the 1970s is the lack of a regulatory mandate.

“Most for-hire carriers limit their exposure to volatility in fuel prices by imposing a fuel surcharge on the goods they transport. Retailers, in turn, typically pass on these fuel surcharges to consumers,” the report says. “That means for-hire truckers have less incentive to invest in technologies that reduce the fuel use from heavy-duty trucks.”

A strong standard would ensure that truck and engine makers bring more fuel-efficient technologies to market, Cooke explained. Without a mandate, manufacturers are reluctant to invest in developing new technologies.

UCS offers few specifics as to these “cost effective” and “within reach” technologies, although Cooke broadly notes the potential for improved trailer aerodynamics, engine waste heat recovery, more efficient shifting with automated transmissions and low rolling-resistance tires.

“Strong standards will save carriers and shippers billions of dollars in fuel costs—savings which can be passed on to consumers,” Cooke said, also noting the positive environmental impact.

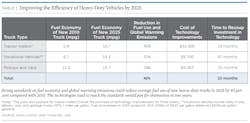

The UCS report calls for a 10.7 mpg target for tractor-trailers by 2025, compared to the 5.8 mpg average in 2010, a 46% reduction. Vocational vehicles would get 14.3 mpg, up from 9.7 (32%), according to the plan. (See Table 1.)

“Precisely how to get there and encourage the technologies to be deployed is up to the agencies,” Cooke said. “This is where the industry could get to. EPA and NHTSA, do your job and help them get there.”

GHG Phase II

An Obama administration initiative, the National Highway Traffic Safety Administration (NHTSA), along with the Environmental Protection Agency (EPA), has begun work on Phase II of its greenhouse gas standards for medium- and heavy-duty vehicles. The initial standards became effective Jan. 1 last year for model year 2014 trucks, and are set to be strengthened with model year 2017. Phase II would target 2018 and beyond.

In comments filed last summer for a NHTSA notice of intent, American Trucking Assns. called for “national harmonization” of all standards for the trucking industry – including standards under Phase II.

To ease the financial burden on truck buyers, ATA supports an 18-month or less ROI on all technologies under Phase II and encourages the agencies to more accurately account for both projected equipment and operation and maintenance costs.

“Our recent experiences with untested emission reduction technologies in 2002, 2007, and 2010 speak volumes,” ATA writes. “It was not uncommon to see engine warranty claims per model year of nearly 200 percent on an annual basis. The trucking industry has learned a hard, financial lesson from these recent technology failures and will not accept further technology-forcing standards that have not had sufficient lead time for development and testing.”

In its comments, the Owner-Operators Independent Drivers Association also focused on cost and real-world results.

“The most crucial consideration is that a more affordable and reliable truck is more likely to be purchased at an earlier date by someone who is considering a new truck,” OOIDA says.

The association also suggests that a seemingly positive environmental requirement can turn into a negative one for safety, and cites the optional use of automatic engine shutdown switches under Phase I.

“While reducing wasteful idling time is a very laudable goal and one that drivers who pay for their own fuel are extremely aware of, the requirement in Phase I that the driver have a limited ability to manually override the switch has the opportunity to result in unintended negative safety consequences,” such as inadequate driver rest if a driver has limited control over the cab climate when parked.

Truck, engine and trailer makers weighed in as well, with most pointing to the difficulty of developing a rule to address such a varied and complex industry as trucking.

Volvo Group even pointed out that congestion mitigation, smart highway systems, permitting longer combination vehicles, improved shipping logistics and packaging would substantially reduce truck fuel consumption.

About the Author

Kevin Jones 1

Editor

Kevin has served as editor-in-chief of Trailer/Body Builders magazine since 2017—just the third editor in the magazine’s 60 years. He is also editorial director for Endeavor Business Media’s Commercial Vehicle group, which includes FleetOwner, Bulk Transporter, Refrigerated Transporter, American Trucker, and Fleet Maintenance magazines and websites.