Grease is critical for keeping your rigs safe. But if you aren’t an expert, using grease correctly can be like trying to solve a mystery. While conventional wisdom may suggest one thing, the truth may be entirely different.

Although every fleet owner is familiar with grease, there are many misconceptions when it comes to application technique, color compatibility, how much to use and more. Read on to learn more about three common grease myths.

MYTH: All greases are the same

While there may be similarities between various types of grease, they can actually vary quite a bit. Grease is made of three components — the liquid, the thickener and the additive. The thickener is what determines compatibility between greases. Not all grease thickeners are compatible, so when choosing a grease, it’s important to know the type you are currently using and what thickener it contains. From there, you can determine what is compatible and what specific conditions your grease needs to address.

You should also ensure you’re selecting the correct NLGI grade for your rigs. The NLGI grade is an industry wide number system that helps determine the thickness of the grease. The higher the NLGI grade, the thicker the grease. In warmer months, you’ll likely want to use a grease with an NLGI grade of 2, which is considered a “normal” grease appearance having the consistency of peanut butter. As the weather gets colder, switching to a 1, 0 or 00 NLGI grade grease will allow your fleet to handle the colder temperatures better, as these grades of grease are softer or fluid.

MYTH: More grease is always better

Many people think more is better, but when it comes to grease, over greasing can cause significant issues. It’s important to monitor your grease application to ensure you are applying the appropriate amount of grease. You don’t want to overpack grease to the point where it can’t lubricate correctly. This is especially true in a bearing. Bearings have seals, and when you’re applying grease, you want to have enough to protect the component, but not too much to blow out the seal. If the seal is compromised, dirt, debris, and water can enter your system, putting your rigs at risk.

While monitoring the amount of grease you are applying is key, greasing regularly also benefits your fleet. Greasing with the correct amount consistently allows a film to be created between the metal to keep components protected longer and your fleet on the road.

MYTH: The color of the grease determines the application

A big misconception is that the color of grease indicates its application. For example, a red grease handles higher temperatures best or a blue grease is better at sealing out water. The truth is the color is only important from a visual standpoint, it doesn’t determine the best application or compatibility of greases. The color is just a dye and shouldn’t be the deciding factor for which grease to use.

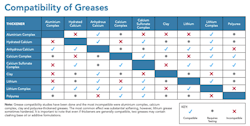

When it comes to color, many people think that when switching products, the color of the grease should remain consistent. That’s not always the case. The key ingredient to pay attention to when switching greases is the thickener, not the color. If you’re thinking about switching your grease, take a look at our Compatibility of Greases chart to help you determine the best option for your fleet.

Selecting the right grease for your fleet can be tough. Keep these tips in mind when making your next grease selection, and you’re bound to keep your trucks on the road for the long haul. For more information and to match the right lubricants to your fleet, use the Cenex equipment lookup tool.

About the Author

Kyle Parker

District Manager, CHS Lubricants

Kyle Parker has over twelve years of lubricant sales experience with CHS Inc. Parker holds a Bachelor of Science degree from UW-Stevens Point and has worked for CHS since 2008. He is currently a North Region District Manager supporting dealer customers and local sales teams in Wisconsin and southern Minnesota.