Wheel-end monitors: From system to data to prevention

The sensors are tiny in wheel-end monitoring systems, but they are powerful.

The TraX from Gothenburg, Sweden-based SKF looks different but functions very similarly to ConMet's PreSet Plus SmartHub.

The SKF TraX mounts to any wheel of a heavy-duty vehicle and wirelessly transmits data to an onboard transponder. That data on wheel-bearing vibration and temperature is then relayed to a maintenance location or the professional truck driver’s smartphone app, which alerts fleet technicians and the driver long before a failure in the wheel end or hub or tire or anywhere else occurs. If a thermal event is detected, the truck’s driver is notified immediately to pull over to avoid a failure that could be catastrophic—such as those wheel-offs.

Hendrickson’s trailer wheel-end monitoring product—Watchman powered by the Sensata Vehicle Area Network—pays attention to tires and the brakes of a wheel assembly, explained Steve Hampson, director of electronic controls for the Woodbridge, Illinois-based aftermarket manufacturer.

See also: Hendrickson introduces Tiremaxx Pro-LB

Hendrickson also is known as a maker and supplier of medium- and heavy-duty mechanical, elastomeric and air suspensions, integrated and nonintegrated axle and brakes systems, auxiliary lift axle systems, parabolic and multi-leaf springs, stabilizers, and bumpers.

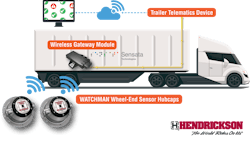

As for Watchman, it relays trailer tire-pressure and wheel-end temperature data to a fleet via the product’s trailer telematics system, according to a Hendrickson fact sheet.

“This common platform allows Hendrickson’s Watchman wheel-end sensor to be used by OEMs to provide crucial trailer data to their customers,” Omar Fernandez, director of marketing at Hendrickson Trailer Commercial Vehicle Systems, said in a statement from the company.

Hampson added additional perspective on thermal events, what causes these events, and what Watchman does for fleet maintenance managers and drivers.

“Brakes are the heat generator,” he told FleetOwner, adding that numerous wheel-end components generate excess temperatures, hubs and bearings among them. “By the very nature of it, the wheel end gets hot by use of brakes. There’s normal operations of brakes, controlled, [but] it’s when it exceeds those thresholds.”

“It’s about wheel-end health,” he added. “That can equate to a lot of things. It’s predominantly focused on the tire, looking at the pressure in the tire system and making sure that it’s level.”

Watchman warns a driver that he or she is navigating the road with deflated tires, Hampson also noted.

See also: The evolution of truck telematics, connectivity

“That’s what leads in some cases to what they call ‘thermal events.’ You’re trying to prevent that thermal event from occurring. We also feel the Watchman product [will identify] slow leaks. Small leaks become bigger leaks, which become even bigger leaks.’ The inflation system is keeping up with it, but it’s something you should have looked at soon. Address thermal events before they happen.”

Watchman has temperature sensors, mounted in the hubcap at the wheel end. “We do get indications if that area starts heating up” beyond normal operation, he said. “Another indicator of problems.”

Early warnings of low tire pressure or leakage and/or elevated temperatures can help minimize the cost of repairs and maintenance of crucial wheel-end components. Watchman’s hubcap-mounted, battery-powered wheel-end sensors transmit wireless signals to the gateway module, collecting the data and acting as the trailer’s communications hub. The information will be transmitted from the gateway module to the trailer telematics device for transmission to the fleet’s back office.

Just like SKF TraX and ConMet’s PreSet Plus SmartHub do, Hendrickson is working with telematics providers to integrate data from the Watchman wheel-end sensor into their telematic solutions, to provide timely and actionable data for enhanced fleet efficiency and uptime. Watchman gets its sensors from Sensata Technologies.

The role of other systems

Other manufacturers such as Pressure Systems International (P.S.I.) and Bendix emphasize how their tire- and brake-monitoring systems help prevent thermal events.

Jim Sharkey, VP of global sales and marketing for P.S.I., spoke with FleetOwner about PSI’s tire-pressure and temperature-monitoring TireView product.

A warning light becomes visible in the driver’s rearview mirror, allowing him or her to pull over to avoid a catastrophic event. Air escaping through the hubcap vent will audibly identify the problem wheel end.

The TireView “gateway” can be mounted inside or outside the cab of a truck, can even be located inside a trailer, and it can port with certain manufacturers’ electronic logging devices.

“Depends on the configuration of vehicles,” Sharkey said. “Right now, everybody wants smart trailers, so they want all the data going to one location. We’d rather integrate with somebody else’s platform. The important stuff is the data. We don’t care how it gets there. We’re gonna help you learn when there’s a problem.”

Another P.S.I. product, TireView LIVE, supplies tire analytics to the fleet’s existing telematics provider. “What we do with all this data is the TireView Live, the portal that gets the data,” he explained. “We store the data, which allows the user to do reports on it. When did I pick up my puncture? When did my temperature start to go up? Sometimes there’s a brake issue, not a tire issue. Sometimes slack adjusters in brakes are not adjusted properly, causing ‘brake drag.’ They can catch brake component issues before [the parts] must be replaced.”

Bendix weighs in with its own TPMS system, SmarTire, but sensing technology added into the system can detect elevated temps within the air disc brakes (ADB), providing early warning for when pads are nearing their replacement interval. It provides a signal via telematics that fleets can use to schedule maintenance.

The system helps lower maintenance costs by reducing the need for technicians to measure friction and by optimizing friction replacement schedules.

Since the system provides alerts when pads are reaching the point of replacement, it protects costly ADB components, such as rotors, from being damaged by worn-out pads. Both systems are also linked to Bendix’s ACom PRO diagnostic software.

The key to addressing wheel-end and tire problems before they become failures and even emergencies is the technology. Monitoring the tire and wheel area of trailers and tractors has come a long way in the last 10 to 15 years.

Using the technology can reduce downtime in the shop and help avoid repairs that are expensive to fleets by catching problems early.

Teacher of technicians weighs in

And a veteran technician’s view on these wheel-end monitoring technologies?

They’re “another set of eyes in the maintenance arena, to catch things that are preventive,” said Bryan Lewis, an ASE master truck technician and former instructor who retired from wrench-turning five years ago but now works as a consultant. “We have to up our preventive maintenance game. The more eyes and ears you have on that vehicle, the better, to catch something possibly catastrophic.”

He said from his limited exposure to wheel-end monitoring technology, it can be used to ease drivability complaints. “I’m talking about the shakes and shimmies. With this vibration detector, it’ll point you to which wheel is potentially creating this problem.”

“I’m an advocate for telematics and data,” Lewis added. The technology, however, “doesn’t replace the basics. We still have to install the wheel seal properly, adjust the wheel bearing properly, so forth. I can’t echo enough the basics, but this technology is another set of eyes. It’s just another tool for the toolbox.”

This is the second part of a feature on wheel-end monitoring that ran in the July issue of FleetOwner magazine. Part 1 appeared on July 12 on fleetowner.com.

About the Author

Scott Achelpohl

Managing Editor

Scott Achelpohl is a former FleetOwner managing editor who wrote for the publication from 2021 to 2023. Since 2023, he has served as managing editor of Endeavor Business Media's Smart Industry, a FleetOwner affiliate.