Next potential use of 3D printing in trucking: Lightweighting

Just when we thought we'd seen all that was going on with 3D printing that could affect trucking and automotive, Ford Motor Co. — an OEM that's been pioneering the use of this technology for some years now — says it's looking into large-scale 3D printing and another potential benefit fleets will readily recognize: lightweighting.

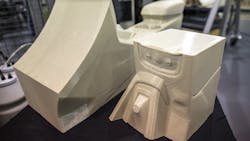

Ford is testing out large-scale 3D printing with Infinite Build printers from Stratasys, noting it's the first manufacturer of its kind to do so. Trucking execs can read between the lines a bit and consider the possibilities watching a new video Ford has put out to showcase the technology. "Imagine a 3D printer as big as a room, capable of printing auto parts of practically any size — even something as big as a 6-ft. spoiler," the video notes.

"It fabricates 3D-printed plastic parts that are lighter than cast metal parts, [which is] designed to lead to more fuel-efficient vehicles," it continues. "It's perfect for low-volume vehicles like race cars, making them more cost-efficient." Also in terms of low-volume parts, Ford also says it's exploring 3D printing up custom parts its clients want.

These large Stratasys 3D printers can keep working when everyone goes home. Ford points out that when the printers run out of material, the machines can robotically reload and continue printing "for hours — days, even."

The OEM notes in a release yesterday 3D printing's potential to make equivalent parts that are just as strong but reduce weight considerably vs. metal parts. The vehicle spoiler mentioned above, for example, "may weigh less than half its metal counterpart."

Ford spells out the benefits 3D printing offers in making up production tooling much faster and at much lower cost, speeding ideas and production to market. Other manufacturers have begun 3D printing some slower-moving inventory parts like certain maintenance parts for trucks. But Ford also points out the current limitations of the technology even in describing its further potential.

"3D printing is not yet fast enough for high-volume manufacturing, but it is more cost-efficient for low-volume production," the OEM states. "Additionally, minus the constraints of mass-production processes, 3D-printed parts can be designed to function more efficiently."

Watch more from Ford below:

About the Author

Aaron Marsh

Aaron Marsh is a former senior editor of FleetOwner, who wrote for the publication from 2015 to 2019.