Fleets are finding more opportunities to increase productivity and enhance operation efficiencies as trailer technology evolves.

“Smart trailers offer a wide range of advantages and benefits that include but are not limited to enhanced visibility, improved safety, regulatory compliance, cost savings, data-driven decision making, and customer satisfaction,” CJ Biank, global market manager at Grote Industries, said.

Connected trailers improve fleet performance by helping manage assets, noted Mark Johnson, EVP and chief marketing officer of Clarience Technologies. “Fleets can optimize routes, monitor cargo conditions and the integrity of sensitive shipments in real time, ensure regulatory compliance, have in-depth insights into trailer health, and manage maintenance schedules,” he said.

“Advanced trailer telematics solutions combined with analytical capabilities enable fleets to reduce downtime, save fuel, and enhance safety,” Johnson added. “Overall, connected trailers save money.”

According to Bryan Dempsey, VP of engineering at Peterson Manufacturing, providing fleets with real-time equipment status is invaluable. “Trailers can now be safer both for the driver and other travelers while also giving fleets and customers better visibility into the status of their loads.”

“The preventive aspect of a connected trailer for its power to prevent an accident or unnecessary delays in delivery cannot be emphasized enough,” Dempsey added. “With better information comes the ability to make better decisions.”

For Dan Forthoffer, corporate director of R&D at Phillips Industries, the value of connected trailers is driven by information. “Data from those solutions allows fleet managers to predict usage and size their fleet accordingly. It lets dispatchers determine where the trailer is, whether it’s loaded or unloaded, and whether or not it is roadworthy,” he said. “Sophisticated systems will pipe the data directly in the company’s transportation management system for real-time analysis and reporting to prevent costly mistakes such as missed pickups and incorrect deliveries.

“Depending on the equipment installed, the amount of data collected, and the attention it is given, a connected trailer can conservatively yield a 20% increase in productivity,” Forthoffer continued. “In other words, a fleet of 80 connected trailers can easily be expected to do the same work as 100 of their non-connected counterparts.”

Today’s and tomorrow’s solutions

At Stoughton Trailers, dry van models are now compatible with the Auto Connect system of Electrans Technologies Ltd. “With this system, the driver stays safely in the cab,” Ron Jake, director of marketing, explained. “With a push of a button, Auto Connect automatically couples the tractor and trailer’s air, seven-way electrical, and CAN bus or other communication lines. In seven seconds, all lines are securely connected and fully operational with signals flowing freely in both directions.”

An upgraded, optional coupler on Stoughton dry van trailers is designed to accommodate the new Auto Connect system. A slot on the front bolster houses and protects the Auto Connect receiver. The Electrans receiver can be installed, connected, and ready for use in as little as an hour on new trailers. In addition, Stoughton made the technology backward compatible with dry van trailers, allowing it to be used on tractors and trailers with legacy connections.

Jake noted that Stoughton sees continued growth in future fleet adoption of trailer connectivity systems. “Trucking companies that are looking to optimize the use of their assets and those that are on a path toward autonomous operations will take advantage of these solutions,” he said.

Forthoffer said Phillips Industries has focused on two major areas of improvement in terms of trailer connectivity. A new wireless backup camera, known as REAR-VU, is included. It allows drivers to download a mobile app and, from inside their cabs, view streaming video from the rear of any trailer that is equipped with this camera.

“This is a huge step in driver situational awareness and is sure to make the environment around a truck much safer and drivers far more comfortable,” Forthoffer said.

“We’re also now in the process of releasing our new T/T Pair QCS socket,” he continued. “The device is an instantaneous solution for determining tractor-trailer pairing. It is installed the same way as a regular J560 QCS; when a trailer is connected, it transmits the pairing instantly to any device via BLE, so there is no way to confuse the pairing.”

Forthoffer said Phillips will soon launch a new EC47 connector to replace the existing J560. The EC47 offers four 10GBASE-T1 capable Ethernet networks, two additional CAN interfaces, four more auxiliary circuits, and a backward-compatible J560 interface so fleets can order new trucks and trailers with it and still connect with the older equipment running J560.

“The holy grail of trailer connectivity is to get all the information available on a trailer to the tractor in real time so the driver can instantly react to anything that goes awry,” Forthoffer stated. “Although we don’t necessarily see this as a replacement for traditional trailer telematics, we do see it as a huge step forward in safety, security, and driver comfort.”

The 4SEE by Grote offers tractor-trailer connectivity with vital trailer data, CJ Biank reported. “Since it can connect to a fleet’s choice of sensor providers, there is no need to retrofit trailers to one set solution,” he explained.

“Additionally, in partnership with Stoneridge we’ve incorporated their rear-view camera into our smart trailer product suite,” Biank said. “The new product uses the standard J560 7-way connection to deliver video from the back of the trailer to a display in the cab with virtually no latency.”

“As trailer technology advancements continue to be made in the form of advanced telematics and diagnostic systems, there will be a requirement to support higher data transmission rates,” Biank continued. “Updating the standard J560 to accommodate this would help to ensure a more efficient data flow between the tractor and the trailer.”

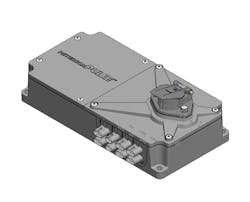

The PetersonPULSE smart trailer system is the company's latest connected-trailer technology. “It offers individual light out detection,” Bryan Dempsey explained. “The system monitors current draw for each individual lamp so drivers will know not just that a light is out, but specifically which light it is. The solution is completely customizable based on the specific needs of each fleet.

“We anticipate that the future of connected trailers will be intertwined with that of the advancement of autonomous vehicles,” Dempsey said. “Trailers equipped with sensors and communication technology will become increasingly integrated into autonomous vehicle systems. This will enable them to communicate with other vehicles, infrastructure, and centralized control systems.”

At Clarience Technologies, the Road Ready trailer telematics solution provides fleets with in-depth insights into trailer health, Johnson said. “Powered by our Fus1on platform, it integrates data from over a dozen LogIQ smart trailer partners,” he explained. “This comprehensive approach allows fleets to monitor everything from brakes, tires, and wheel ends to the trailer’s refrigeration unit.”

Going forward, Johnson noted, software innovations will genuinely revolutionize the trailer connectivity landscape. “A genuine Internet of Things platform has the remarkable ability to gather data from an almost endless array of sources, whether it's through an API or any other format; link up crucial data points; and create a network of insights that can transform how fleets operate,” he said. “And by marrying connectivity with AI capabilities, fleets will be able to get recommendations based on their own performance.”

FleetPulse recently launched the next generation of its visibility product FleetPulseGO–Track, according to its CEO, Carl-Christoph "CCR" Reckers. “The system is now easier to install and use, more durable, and has a longer battery life,” he said. “Further, we added more sensor capabilities to our FleetPulse PRO offering, and our FleetPulse cloud-based platform has new diagnostics capabilities and new insights dashboards that help inform day-to-day decisions. We’ve also frequently updated our hardware over the air, and we release improvements to our software every two weeks.

“We’re very excited about the role AI can play in interpreting trailer telematics data,” Reckers continued. “For example, AI could prioritize trailers for maintenance, order any required parts, and add VINs to a technician’s schedule. For cargo security, we envision AI processing claims automatically, based on video footage and sensor data.”

Keys to connectivity

Carl-Christoph "CCR" Reckers, CEO of FleetPulse, pointed out that connected trailers can allow all types of fleets, including for-hire, private, and leasing operations, to improve their business in three key areas:

- Productivity by knowing where trailers are located, how long they have been idle when they become loaded/unloaded, and the size and weight of the cargo.

- Safety by proactively informing preventive maintenance intervals and addressing issues.

- Security by monitoring loads with video feeds or sensors and receiving alerts about door openings.

Reckers also listed ways fleets can realize a return on investment from connected trailers. Depending on their use case, he said, savings can come from improved asset uptime and better use of driver hours of service, fewer and less expensive cargo claims, and lower costs for asset recovery, accident avoidance, and reduced maintenance costs.

Informing fleet decisions

For CJ Biank, trailer connectivity improvements enable fleets to address top areas of concern, including ensuring safe operation and improving efficiency more easily. “Trailer connectivity has bridged this gap and is providing fleets with the tools to make informed decisions based on data being delivered directly from their trailers,” he said.

As FleetPulse’s Reckers explains it, introducing trailer telematics technology can prove to be an extremely effective solution when fleets are increasingly focused on asset uptime and cost management, out-of-service violations during inspections, and their impact on businesses and insurance costs as well as an increase in cargo thefts and claims.

“All of those can be addressed with trailer telematics technology that provides actionable insights for proactive management of asset productivity, safety, and cargo security should an issue occur,” he added.

“In the last several years, connectivity through telematics has grown beyond knowing asset location as a means of addressing fleet size, increasing utilization, and improving efficiency,” Phillips’s Forthoffer said. “It now includes asset condition, including roadworthiness, load status, and other critical parameters related to equipment functionality.

“All of this information, when provided to the back office, offers a tremendous amount of opportunity to reduce operating costs, increase margins, and avoid costly mistakes,” he continued. “That’s why, when utilized properly, fleets have seen a significant return on their trailer telematics investments.”

The exponential growth in data generated from fleet assets over the past five years has made trailer connectivity technologies more critical than ever, Clarience’s Johnson noted.

“But fleet managers can be inundated with information from trailers and data streams coming from tractors, as well as all parties that interact with the equipment,” Johnson said. “Telematics providers continue to make significant progress in trailer connectivity, not just with more advanced software platforms but also with the ability to combine various data feeds into a single dashboard for a comprehensive view of the entire trailer fleet.”

“Fleet managers who choose to say no to connected trailer technologies should understand that by doing so, they could be exposing their companies to a great deal of risk,” he added.

“The transportation industry is constantly looking for ways to increase efficiencies and safety, reduce downtime, and provide consumers with their goods in the fastest possible time,” said Peterson’s Brian Dempsey. “It is for those reasons that there is an evolution to smart trailer systems and sensing. Connectivity is a must for fleets.”

About the Author

Seth Skydel

Seth Skydel, a veteran industry editor, has more than four decades of experience in fleet management, trucking, and transportation and logistics publications. Today, in editorial and marketing roles, he writes about fleet, service, and transportation management, vehicle and information technology, and industry trends and issues.