Daimler Truck to build scalable truck platform for autonomous driving

Daimler Truck is developing a scalable autonomous truck platform that is suited for SAE Level 4 autonomous driving, including redundancy systems needed to achieve safe and reliable operations.

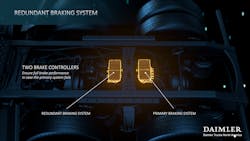

According to Daimler, the four key areas with a redundant architecture are the braking system, the steering system, the low voltage power net, and the network communications. In case that any of the primary systems encounter a fault, the Level 4 vehicle will be able to monitor, assess, and deploy its backup systems to control the truck safely.

“Every smart autonomous driving system needs a strong foundation: Our Level 4 vehicle platform based on the Freightliner Cascadia is ideal for integration of autonomous software, hardware and compute,” said Peter Vaughan Schmidt, head of the autonomous technology group at Daimler Truck. “It can significantly contribute to enhancing safety in traffic thanks to its redundancy of systems and a multitude of sensors. It brings us much closer to our vision of accident-free driving.”

Daimler Truck’s L4 truck platform—based on Freightliner’s Cascadia—is being developed for Waymo Via based on their specifications. A first version of the truck has already been delivered this year for integration of the Waymo Driver, the autonomous driving system.

According to Daimler Truck, if a fault is deemed critical to the operation of the vehicle, the autonomous driving system will allow the truck to follow a safety protocol and be able to execute a “minimal risk maneuver” to come to a safe stop.

The redundant system architecture

More than 1,500 new and unique requirements have been identified by Waymo Via. The engineering team at Daimler Trucks North America LLC (DTNA) is developing and implementing these requirements during the vehicle development process. For example, while today’s pneumatic braking systems have failed operational attributes, Daimler Truck’s Level 4 vehicles have an additional layer of electronic redundancy, using two electronic control units (ECU)—a primary and a secondary system. Together, they work to ensure full brake performance, to safely execute a minimal risk maneuver in case one system is not operating properly.

According to Daimler, the same logic applies to the steering system that has been enhanced by having two servo motors. In case of an electronic or hydraulic failure, the backup servo motor also receives the requested steering angle from the autonomous driving system and can react accordingly.

Constant communication between these key systems ensures that there is no loss of critical information flow among the controllers. Daimler Truck has included a secondary communication network to key devices, which is also protected by cyber security requirements. As for the demanding power consumption by all the ECUs and sensors in an autonomous truck, a robust low voltage power net is required. Exclusively developed at DTNA, the power net system ensures constant energy flow to critical systems.

Scalable solution for customers

In combination with a third-party autonomous driving software, this redundant chassis offers customers full SAE Level 4 autonomous driving capabilities. As part of Daimler Truck’s dual track strategy, the truck manufacturer is working together with two strong autonomous technology partners, Waymo Via and Torc Robotics, offering multiple routes to commercialization. Daimler Truck has the capability to tailor and scale the Level 4 truck chassis to the autonomous driving specifications of both technology partners.