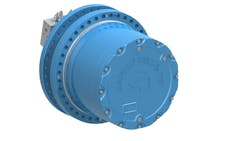

Dana Incorporated has launched a new series of eight Spicer Torque-Hub drives, expanding the company's offering of drive and motion technologies for crawler cranes and other large tracked vehicles.

With torque ratings from 80,000 N-m up to 450,000 N-m, the new drives offer flexible packaging and gear ratios to meet manufacturer preferences for tracked and wheeled applications.

Spicer Torque-Hub drives can be packaged with Brevini hydraulic pumps and motors to offer an optimized solution that delivers superior power density, increased torque and efficiency at start-up, and smooth starts and stops.

The first three models in the new series of drives are currently available for field testing by original-equipment manufacturers, with production expected by the end of this year.

"The Torque-Hub brand has delivered performance, durability, and reliability to small- and medium-sized off-highway applications for nearly 50 years," said Aziz Aghili, president of Dana Off-Highway Drive and Motion Systems. "By extending Spicer Torque-Hub technology to the largest, most heavy-duty off-highway applications, Dana is ideally positioned to provide drive technologies across our customers' entire range of equipment."

Spicer Torque-Hub drives offer flexibility

Dana offers more than 100 versions of Spicer Torque-Hub drives, starting at 1,000 N-m, for a broad spectrum of applications including self-propelled sprayers, mobile elevated work platforms, compact track loaders, and crawler cranes. They feature a compact design with a steerable four-wheel-drive configuration that delivers exceptional maneuverability. Also, Spicer Torque-Hub wheel drives can be easily integrated with Spicer Central Tire Inflation Systems.

Spicer Torque-Hub drives can be packaged with high-performance electric motors from the Dana electrodynamic product portfolio to deliver integrated e-Hub systems with superior efficiency.

Dana leverages its global footprint to accelerate delivery times to customers' final vehicle assembly facilities by manufacturing Spicer Torque-Hub drives in the United States, Italy, India, and China.

Dana's extensive support for cranes

The new Spicer Torque-Hub track drives join Dana's large and growing portfolio of drive and motion technologies for manufacturers of tracked and wheeled cranes.

In 2018, Dana introduced a series of 13 high-performance Brevini winches for cranes and other applications with lift capacities from 1.1 tons (990 kg) to 33 tons (30 tonnes). Each winch in the series features a compact, high-speed piston motor for efficient operation.

Additionally, Dana supports the work functions of cranes with a wide selection of Brevini slew drives, hydraulic pumps and motors, and proportional directional valves.

For rough-terrain cranes, Dana engineers and manufactures advanced Spicer-branded transmissions, heavy-duty steer axles, and driveshafts that are fully customizable with additional features and configuration options to achieve the highest levels of fuel efficiency and productivity.