Wheel installation: It looks so easy but has hard consequences

Key takeaways

- Training is crucial for ensuring safety and preventing accidents, especially after past incidents.

- Drivers must take an active role in ensuring proper procedures are followed and advocate for safety even in reputable shops.

- Effective communication about safety measures is vital for the trucking industry to rebuild public trust after serious incidents.

Professional tire technicians make their jobs look pretty easy. There's a rhythm to the way they work. They use gravity rather than brute force to get tires on and off the rims when there's no machine available. They use the tire irons with mystical dexterity to get tires off the wheel, and later, the wheel back up onto the hub. With a few deft strokes of the impact wrench, the fasteners are tightened down, the bills are signed, and the truck is back on the road.

If only that were the whole story.

I've witnessed this little dance routine about a dozen times over my 20-year driving career. But one particular tire change stands out in my mind. It was in Belleville, Ontario, about 100 miles east of Toronto, in February 1997.

At the time, Ontario had just wrapped up a coroner's inquest into wheel separations. A year earlier, two motorists had been killed in separate incidents by dual wheels that had parted company with their truck. The incidents occurred about two months apart.

Before the double-fatality incident, the province had amended the Ontario Trades and Qualifications Act, requiring persons involved in wheel installations on commercial vehicles to hold a certificate of training in proper installation procedures.

I was acutely aware of the public's sensitivity to wheel separations. At the time, I was a member of the Ontario Trucking Association's Knights of the Road Team, roughly equivalent to the American Trucking Associations' America's Road Team. I had made about a dozen public presentations to groups around the province, touting how seriously the industry was taking the issue of wheel separations. I had faced angry audiences, and I understood their angst.

So, there I was one frosty morning in early 1997, having a tire changed in a "reputable" tire shop associated with a major brand. The technician was not following proper procedures when reinstalling my wheel following the tire repair.

I refused to sign the work order. That set in motion an unpleasant confrontation between me and the tire guy, and eventually his boss and my boss. I demanded the wheel be removed and then properly installed, including the cleaning of the mounting surfaces and proper torquing of the fasteners, etc. It was then that I learned the tire shop didn't possess a calibrated torque wrench, even after three years of very public handwringing over three fatal wheel separation incidents and the implementation of a training and certification program for wheel service technicians.

With the modest public profile I had with the Road Knights, I absolutely couldn't risk a wheel coming off my truck. Up to that point in my career, I couldn't have cared less about how my tires and wheels were installed.

Don't ask, don't tell

Wheels continue to separate from trucks at an estimated rate of about three to five incidents per day nationwide. That estimate is based on the number of reported occurrences. The ones we hear about usually involve vehicle damage and often personal injury. Occasionally, someone dies. Who knows how many we never hear about.

If the truck is out of dashcam range and the wheel rolls off into a cornfield and the driver manages to make it to a shop without being noticed, so much the better, right? Make the repairs and carry on.

Believe it or not, there hasn't been a serious examination of wheel separations in the U.S. since the early 1990s. The National Transportation Safety Board, prompted by five fatalities resulting from three separate wheel-offs over a three-week period in the fall of 1991, investigated and issued conclusions and recommendations in September 1992.

Some of those recommendations are now outdated because wheel-end components have evolved, but several conclusions regarding the causes of wheel separations still, unfortunately, hold true:

- “… the leading causes of wheel separations from medium/heavy trucks are improper tightening of wheel fasteners and bearing failure; both are the result of inadequate maintenance.”

- “Under-tightening of wheel fasteners usually results from the failure to follow recommended wheel maintenance practices, such as always using a torque wrench, following proper tightening procedures, using only compatible components, and avoiding paint buildup, debris, oil, or rust between wheel fasteners, threads, and mating surfaces.”

- "Failure by carriers and mechanics to adhere to recommended maintenance guidelines published by wheel manufacturers."

Ontario digs deep

A similar scenario unfolded in Ontario four years after the NTSB issued its wheel separation report. Two motorists died in separate incidents within weeks of each other after being struck by flying sets of dual wheels. And less than a year later, two more motorists died when the car they were in suffered the same fate.

The latter event raised many eyebrows as it was believed that systems had been put in place supposedly to prevent such occurrences.

The following are among the actions taken by Ontario between 1995 and 1997:

- Establishing mandatory certification for wheel installers

- Updating the vehicle out-of-service criteria regarding loose, missing, or damaged wheels and wheel fasteners

- Introducing a legal change to the province's Highway Traffic Act, making wheel separation an "absolute liability offence" as opposed to a "strict liability offence"

The latter change removed the ability to contest the charge using a due diligence defense. Fines ranging from $10,000 to $50,000 could be levied against the carrier, the wheel installer, or the driver. Wheel separations remain an absolute liability offense in Ontario to this day.

The combined action had the desired effect. The number of reported wheel-off events declined by more than 50% in subsequent years, and they remain statistically lower than before the changes were implemented.

See also: These are not your Uncle Floyd’s drive tires

Ontario's ongoing research

Ontario changed the reporting protocol for wheel-off incidents in the early aughts. A standard form was created for law enforcement with general and specific information related to wheel separation. Data collection was centralized within the Carrier Safety and Enforcement Branch of the Ontario Ministry of Transportation. This allowed officials to study the events and come to some conclusions, or at least educated speculation, on what was causing wheels to fall off trucks.

Incidents continue to be investigated and logged, but the most recent published information is current only to 2016. Still, the research done at the time by Rob Monster, a vehicle standards engineer with the Carrier Safety Branch, informs much of what is known today about wheel separations.

Among his findings were the following:

- Trucks (not tractors) and trailers are about equally represented in reported wheel-off incidents.

- Tractors pulling trailers are less than half as likely to lose a wheel compared to trucks or trailers.

- More than 80% of the events investigated resulted from failed fasteners.

- Failed bearings were responsible about 10-15% of the time, with other causes (cracked wheels, axle failures, etc.) responsible for very small numbers.

- The month-to-month distribution of incidents reveals a dramatic increase in the winter months, January and February in particular. This holds true for both fastener- and bearing-related incidents.

- Statistics gathered during investigations between 2000 and 2003 revealed that in 66 of 80 reported incidents (83%), wheel separations due to fastener failure occurred shortly after a wheel had been reinstalled following brake work. It happened in less than 300 miles on at least two documented occasions.

Lamentably, many of the conclusions Monster published in his 2004 report, "Wheel Separations from Commercial Vehicles: Experiences in Ontario," were essentially the same as the conclusions the NTSB published a decade earlier.

We haven't mentioned bearing-related wheel separations here. Statistically, they make up a smaller slice of the pie, but they are still considered maintenance failures. Improperly installed bearings are about equally represented, along with lubrication starvation-related failures. These failures have different solutions than the fastener problems discussed here. Bearing failures will be addressed in a forthcoming article.

Failure to maintain or failure to train?

After more than 30 years of study and analyses, it's safe to say that there's nothing intrinsically wrong with the wheel fastening systems widely used today: hub-piloted wheels and flange-nut fasteners.

The problems appear to stem from improper installation, which essentially comes down to the training and diligence of wheel installers.

We're not casting aspersions on wheel installers, but it's possible that some of them have not been trained properly in the nuanced art of wheel installation.

Here's the rub: The Occupational Safety and Health Administration requires training for anybody who does tire and wheel service on any vehicle over 10,001 lb. registered gross weight. However, the training offered by OSHA is not specific when it comes to the installation process.

"A lot of the training required under OSHA standard 1910.177, Servicing Multi-Piece and Single-Piece Rim Wheels revolves mostly around the safety aspects of demounting, mounting, and inflating tires," Kevin Rohlwing, CTO at the Tire Industry Association, said. "The OSHA training is not very specific on the proper method of wheel installation. OSHA's guidance says to refer to the rim manuals provided by your wheel supplier. There's nothing wrong with those installation manuals, but they are manuals, not training programs."

In other words, the tire and wheel training programs mandated by OSHA don't address the critical final steps in wheel installation:

- Removing debris (rust flakes, excess paint, etc.) from mating surfaces

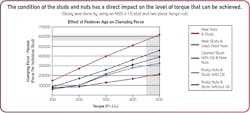

- Ensuring the studs and flange nuts are in working condition

- Cleaning and lubricating the studs and nuts prior to tightening

- Snugging the wheel on properly so that it's correctly seated on the hub

- Ensuring the correct amount of pretension is applied to the studs

- Ensuring the nuts are torqued to the correct value with a calibrated torque wrench in order to achieve the desired clamping force

"To untrained eyes, putting a wheel on a truck is just tightening a nut onto a bolt," Rohlwing told FleetOwner. "That's exactly the way it looks, but that's the furthest thing from the truth."

Also, to the untrained eye, a flange nut is just a flange nut, regardless of its age or condition. However, in a paper titled “Heavy Vehicle Wheel Separations: Exploring the Causes,” author John Woodrooffe suggests that reusing degraded flange nuts could cause problems.

“Testing has shown that as [two-piece] flange nuts age, or when they are reused, their torque/clamping force characteristics can be as little as 50% of the design value. Given that hub-piloted wheels depend exclusively on clamping force to prevent the wheel from separating from the hub, such a reduction in clamp force characteristics represents a significant risk to wheel separation."

Would you expect the newest member of your tire and wheel team to be aware of that? Or even a senior member of the team if he or she hadn't been properly trained?

Torque check vs. retorque

In addition to the steps hinted at above, Rohlwing calls it RIST (remove debris, inspect the components, snug the lug nuts, and torque to spec). The final step in a proper wheel installation is a torque check.

This procedure isn't well understood, and it's often dismissed as impractical. Previously, fleets were advised to "retorque" the lug nuts of a recently installed wheel after around 50-100 miles. For all intents and purposes, it is nearly impossible to meet this obligation. However, a workaround has been developed and endorsed by the industry, including wheel manufacturers, the ATA's Technology & Maintenance Council, and the TIA. It's called a torque check.

After a wheel installation, the vehicle should be driven for five to 10 miles on a route with tight turns and/or uneven surfaces. This helps settle the wheel on the hub. After the drive, the fastener torque should be checked and, if necessary, restored to the desired value.

"There are still a lot of people that don't know about the RIST procedure, that don't know how clamping force is affected by debris on mating surfaces, worn components, and the lack of proper snugging," Rohlwing points out. "They don't understand that, so they think the torque wrench is a magic wand."

Background and training resources

The preponderance of evidence relating to wheel separations gathered and studied over the past 30 years points directly to deficiencies in some fleets' wheel installation procedures. Whether it's a lack of training or simply a matter of tire technicians not taking the time to do the job properly remains a matter for discussion.

Even if your fleet has diligently put the tire techs through the appropriate OSHA training (it's required by law, by the way), they may still lack some vital knowledge and skill. That's not necessarily a shortcoming of OSHA. The purpose of OSHA is not wheel installation; it focuses on preventing workplace injuries. The training offered by OSHA reflects that.

TIA offers three tiers of training, ranging from new hires up to instructor-level certifications. These programs cover all aspects of commercial truck tire service. The Basic CTS 200-level course meets OSHA requirements and is OSHA-compliant, so there's no duplicate training required.

Don't overlook the service and installation manuals published by the likes of Alcoa and Accuride. As noted above, they are reference manuals, not training programs, but they offer valuable insights for wheel installers.

TMC offers its members several recommended practice documents related to wheel and rim maintenance and installation, including:

- RP 237C: Torque Checking Guidelines for Hub-Piloted Disc Wheels

- RP 238C: Troubleshooting Disc Wheel Looseness

- RP 240B: Steel Wheel and Rim Refinishing Guidelines

- RP 656A: Hub and Spoke Wheel Fastener Maintenance

The problem with wheel installation is that the pros make it look easy. Almost anybody could do it, but can anybody do it correctly?

"No. Not if you're not properly trained," Rohlwing emphasizes. "And I think that is where we, as an industry, have gone wrong. We give that job to anyone with a strong back, without explaining what the hazards are and what can go wrong. What are the out-of-service conditions, and how can you tell when a lug nut is worn? How clean do the mating surfaces need to be? How can tire technicians be expected to know all this if they haven't been properly trained?"

About the Author

Jim Park

Jim Park is an award-winning journalist who has covered the trucking industry since 1998. Before that, he racked up 2 million miles as an over-the-road truck driver and owner-operator pulling tank trailers. He continues to maintain his CLD. Park's previous driving experience brings a real-world perspective to his work.