International confirms S13 powertrain is ‘EPA27 ready,’ offering fleets consistency and efficiency

Key takeaways

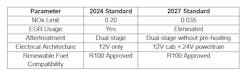

- International S13 EPA 2027 ready: The updated S13 Integrated Powertrain meets the stringent EPA 2027 emissions requirements, specifically lowering nitrogen oxide (NOx) limits from 200 mg to 35 mg/hp-hr.

- Maintenance simplicity and consistency: The 2027 S13 maintains 90% hardware carryover from the current S13, offering fleets a reliable, compliant solution that minimizes complexity, service tool changes, and technician training costs.

- Key new powertrain technologies: The new S13 system features Variable Valve Timing (VVT), Variable Valve Braking (VVB) (boosting braking power to 570 hp), and a 24V Powertrain Architecture for improved cold-cranking and sensor speed.

- EGR-cooler elimination: The S13 was designed from a clean sheet to operate without an exhaust gas recirculation (EGR) cooler, eliminating a common maintenance headache and future-proofing the engine for the 2027 rule.

While much of the trucking industry awaits more clarity on the looming EPA 2027 emissions mandates, International Motors says its updated S13 Integrated Powertrain will offer fleets a compliant, “reliable solution without unnecessary complexity.”

A little more than a year after its rebrand, the Traton Group-owned OEM announced that its 2027 International S13 Integrated Powertrain meets the Environmental Protection Agency's (EPA) emissions requirements for 2027 model-year heavy-duty trucks. Last November, the EPA signaled it would likely reduce cost-specific portions of the regulations, such as lengthy warranty and useful life requirements, while maintaining emissions requirements that lower nitrogen oxide (NOx) limits from 200 milligrams to 35 milligrams per horsepower hour.

“I think there are non-NOx pieces of the regulations that we’re still waiting for some clarity on,” Dan Kayser, International’s EVP of commercial operations, told industry media on January 7. “So we’re marching as though this happens in January of 2027. We have no reason to believe that won’t be the case.”

The S13 development began in 2017 (when the company was still Navistar and before Traton acquired the U.S. OEM). When it launched in 2022, chief executive Mathias Carlbaum said the powertrain would include the company's final internal combustion engine.

What's new and what's remaining in International's 2027 S13 Integrated Powertrain

Unchanged in the 2027 model

- S13 Engine: No EGR cooler, fixed-geometry turbo with smart DEF dosing, dual overhead cam design, 23:1 compression ratio.

- T14 Transmission: Compact 14-speed with planetary gearset, electronic clutch actuator, integrated PTO options, and advanced oil lubrication system.

- Dual-Stage Aftertreatment: Same size and packaging, providing extended service intervals.

New for 2027

- S13 Engine: Variable Valve Timing (VVT), which enables Variable Valve Braking (VVB) for improved braking performance, closed crankcase breather, and oil centrifuge.

- T14 Transmission: 24V Transmission Control Module with predictive shifting using GPS/topography data.

- Electrical Architecture: Reduces complexity by using a standardized 24V electrical architecture across the entire powertrain platform, with 24V alternator, starter, and engine controllers to improve cold-crank performance and durability while retaining a 12V cab and chassis electrical system for battery accessories and body controls.

International’s S13 promises fleet maintenance consistency, fuel efficiency, better driver experience

Kayser said that International has been preparing for EPA 2027 for years with a focus on keeping it simple for fleet maintenance. Retaining 90% of the 2022 S13’s hardware, the 2027 platform offers similar fuel economy, driving experience, and weight, while fleets can expect consistency in service tools, parts, and technician training.

With more than 700 million customer miles driven on the current S13, International executives told industry media that the EPA 2027-compliant equipment can provide fleets with peace of mind at a time when truck orders are down—and more freight-focused fleets are pushing equipment cycles to their limits as freight markets remain sluggish.

Their pitch to fleets is not just that the new S13 complies with federal regulations; it’s that it improves trucking operations over the road or in vocational sectors.

“I think the No. 1 benefit, obviously, is the improvement in efficiency, the fuel economy, and bringing it in such a way we actually think the experience we’re creating for the driver is better than the experience they currently have with those legacy products,” Kayser said.

He said those reasons are driving some current customers to keep up or accelerate replacement cycles. “The market’s still very weak—and we expect ‘26 to at least start out in a fairly weak position, then we’ll see where it goes,” Kayser said.

But he noted that maintenance costs only grow as trucks age. “When we can bring a more simplistic product with great reliability, excellent driver benefit, and the benefit of a significant fuel economy improvement over what would be replaced, it starts to become a pretty compelling narrative.”

What the S13 offers vocational and small fleets

David Hillman, VP of integrated powertrain, added that interest in the new powertrain isn't limited to the mega-fleets that typically drive new technology adoption.

"It's not just for someone who's got 10,000 units in operation. Small customers are the ones that are the most eager, I think, to hear more about it," Hillman said. "This is one of the most positive word-of-mouth products that we've had in my 27 years with the company."

That word of mouth is extending into the vocational sector, where reliability often trumps mpg. In Wisconsin, Menzel Enterprises has been integrating the new International HX Series dump trucks into its operations. Todd Menzel, the fleet’s chief operating officer, told FleetOwner that the S13 is simplifying maintenance and operations compared to other fleet trucks that feature engines, transmissions, and PTOs from different manufacturers.

With the S13, “it's a one-stop shop, and that 100% makes my life and my maintenance department's life a lot easier,” Menzel said in December. The truck is “going to go to the dealership, and the dealership can handle everything from front to back, top to bottom, wherever it might be. That's a huge plus. It's kind of a warm and fuzzy feeling that I don't ever have to bring it somewhere else.”

What’s new in the 2027 International S13: VVT, VVB, and 24V architecture

Developed over five years as part of the Traton Group’s global modular system, the S13 was designed from a "clean sheet" to operate without an exhaust gas recirculation (EGR) cooler—a component notorious for maintenance headaches. By eliminating EGR and using a dual-stage aftertreatment system, International claims the engine was effectively "future-proofed" for the 2027 rule, which slashes NOx limits by 82.5%.

During the virtual media roundtable on January 7, Hillman outlined the specific changes planned for MY 2027. While the core engine block, 23:1 compression ratio, and fixed-geometry turbo remain, the updated system will introduce:

- Variable Valve Timing (VVT): To manage engine temperatures during low-load operation.

- 24-Volt Powertrain Architecture: The engine and transmission will operate on a 24V system (common in Europe) to improve sensor speed and cold-cranking performance, while the cab remains on a standard 12V system.

- Variable Valve Braking (VVB): The VVT technology enables improved compression-release braking, increasing braking power from 470 hp to approximately 570 hp.

Market context: When can fleets order the EPA27-compliant S13?

Fleets looking to secure the updated equipment will need to wait a few more months. Kayser expects order boards for the EPA 2027-compliant equipment to open in "roughly mid-2026." Executives declined to share pricing details, which remain in flux, while the OEM awaits the EPA’s final decision on warranty and related EPA27 regulations.

Until then, International is focused on seeding the market with the current S13 and the newly redesigned HV Series vocational truck, which enters series production fully this year.

The 2027-compliant powertrain announcement comes ahead of International parent Traton's 2025 fourth-quarter earnings report, following a weak Q3 for the global vehicle maker. In October, a top Traton financial executive warned that International could post an operating loss during the final three months of 2025.

International technically posted an operating loss in Q3, but it was due to a one-time charge of about $150 million to account for the end of an electric-truck development project. After excluding those costs, the business would have earned an operating profit of approximately $17 million on sales of about $2.1 billion.

That last sales figure was 17% smaller than the second quarter’s and only about half that of the third quarter of 2024. But that comparison looks worse than it would under ordinary circumstances because International’s Q3 2024 sales were artificially inflated by the company catching up on sales it missed earlier in the year due to a supplier production snag.

After a rough 2025 for Class 8 truck sales, in which orders remained below 2024 (and most 2023) levels, North American orders boomed in December, setting the highest monthly total in more than three years—since the prolonged freight recession began in 2022. But analysts this week said that the December surge is more likely to be a blip, as most fleets wait for trucking industry economic fundamentals to improve.

While International has not disclosed its Q4 figures, comparing the first nine months of 2025 to the six previous financial quarters shows the impact of the freight recession and tariff volatility on sales: This year’s three-quarter average is 12,694 compared to more than 19,300 from mid-2023 to last December.

“December’s order strength likely reflects the release of deferred orders along with the early stages of a modest EPA27 NOx prebuy rather than a broader demand inflection,” Dan Moyer, FTR Transportation Intelligence senior commercial vehicles analyst, said.

About the Author

Josh Fisher

Editor-in-Chief

Editor-in-Chief Josh Fisher has been with FleetOwner since 2017. He covers everything from modern fleet management to operational efficiency, artificial intelligence, autonomous trucking, alternative fuels and powertrains, regulations, and emerging transportation technology. Based in Maryland, he writes the Lane Shift Ahead column about the changing North American transportation landscape.