Donaldson streamlines air filtration monitoring through Geotab

ATLANTA— Fleet owners using Geotab’s telematics solution, which tracks data on 450,000 trucks ranging from Class 6 through 8 in North America, will soon be able to receive their Filter Minder air filtration analytics data through the MyGeotab platform, Donaldson Company Inc. announced at the 2019 North American Commercial Vehicle Show.

By pairing a wireless Donaldson pressure sensor to the Geotab Go device, users will gain greater visibility and understanding of what is happening within the crevices of their air filters, such as a particulate build-up that restricts flow and creates fuel inefficiency. The solution is being tested now and slated for a 2020 release.

“We set out to offer a really simple solution for fleet managers,” said Nate Zambon, director of the Filter Minder division of Donaldson. “By integrating our Filter Minder solution into the Geotab platform, fleets that use MyGeotab can receive Donaldson’s comprehensive filter analytics along with all other fleet data on their laptop or mobile device. It will be easy to monitor air filters on individual trucks or fleet-wide, and service them at the optimal time.”

This ensures the air filter is serviced at the optimal time. All trucks are different, and a dump truck in a quarry would likely need a fresh filter earlier than a truck used for freight.

Zambon said “standardiz[ing] all the maintenance practices based just off time or mileage-based intervals really creates a lot of inefficiencies.” Servicing too early means wasting money and exposing complex engine parts to contaminants, while an older filter collects more dirt and restricts air flow, causing the engine to work harder and burn more fuel.

The dashboard takes all the guesswork out and breaks down how the filtration system in each truck is performing.

Donaldson’s plan is to scale the technology to include fuel, lube and hydraulic sensing, offering the potential for exponential cost savings through continuous condition monitoring.

He gave the example of real-time oil condition monitoring. Normally, this is tested at oil change intervals, so a major internal event such as a cracked EGR cooler leaking coolant into the oil may not be discovered. The Filter Minder lube oil sensor would detect this and send an alert far earlier.

Instead of running until normal service and wrecking a $40,000 engine, you change a $2,000 part, he said.

Beating the competition

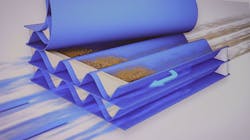

Donaldson also announced the results of a side-by-side study where its PowerCore filters proved to be far more efficient than competition claiming to be similar, restricting 27% less airflow and saving $215 per truck per year in fuel and maintenance.

“Fleet owners are modifying their trucks’ aerodynamics to optimize fuel economy,” said Al Hovda, general manager of Donaldson Air Products. “There are significant savings available in simply staying with PowerCore filters, the same technology that comes off the assembly line as the first-fit filter for leading commercial truck manufacturers.”

The 20-year-old PowerCore comes standard on Freightliner and International trucks. Donaldson recently made its 40 millionth unit this year. For a fleet of 500, this equals $100,000 annually (assuming diesel is $2.92/gal.)

“That’s real money, that’s real value,” Hovda said. “Every day that goes by, that restriction is increasing, causing you more and more fuel penalty.”

The PowerCore also has 26% more capacity for holding contaminants.

“Anyone choosing replacement filters needs to carefully consider total ROI, especially fuel and filter replacement costs,” Hovda concluded.

About the Author

John Hitch

Editor

John Hitch is the editor-in-chief of Fleet Maintenance, providing maintenance management and technicians with the the latest information on the tools and strategies to keep their fleets' commercial vehicles moving. He is based out of Cleveland, Ohio, and was previously senior editor for FleetOwner. He previously wrote about manufacturing and advanced technology for IndustryWeek and New Equipment Digest.