It might be considered a witty cat-and-mouse game if the stakes weren’t so high. But when lives could be lost in worst-case scenarios, having truck drivers disable safety systems in any number of imaginative ways, and for whatever reasons, isn’t the least bit amusing.

At a safety systems seminar at the recent annual meeting of the Technology & Maintenance Council (TMC) in Atlanta, Brad Aller told the many hundreds of trucking industry people in attendance that fleets need to do much more than simply add the new technology to their vehicles.

• This is part 4 in a continuing Fleet Owner series spotlighting speakers and topics from that event; read Part 1, Part 2 and Part 3.

“It’s all about implementation and maintenance,” said Aller, who is regional director, fleet sales and service, for Bendix Commercial Vehicle Systems. “Most of you have this technology today. Do your drivers like it? Are they tampering with it? If you spent thousands of dollars on safety technology and have a driver putting aluminum foil over the radar, you’ve wasted your money.

Technology has changed. Have we taken the time to introduce it to the drivers and technicians correctly?”

Before joining Bendix in 1999, Aller was a trainer at a truck dealership and spent 15 years as an instructor in heavy-duty truck systems and diesel engines. He’s been ASE-certified for 25 years, and emphasized that compliant drivers are key for safety systems to be effective.

“If we put a driver in a vehicle and do not train them correctly, they will not know how the system is going to work,” he said. “The driver assistance is not there to replace the driver. It is there to assist the driver. They need to know what the system does and does not do.

“For instance, take speed-sign recognition. If you go five miles over the speed limit, we give the driver an alert. At 10 miles over we give the driver an alert and take the throttle away for one second. But it does not apply to the brakes, and the driver needs to understand it does not.”

A forceful speaker, Aller queried the audience to make a point.

“How many people here have texted while driving? Or received a phone call while driving? Or have a Dick Tracy watch?” he asked. “As technology changes and we add components in our personal lives, it affects our driving habits. And now that we have wifi in our cars I can send an email instead of a text.”

While technology continually moves forward, drivers are still drivers, Aller noted, and they must be heard.

“We need to listen to them,” he stressed. “A driver that’s in that vehicle day in and day out knows how it should work. And a lot of times when they tell you there’s a problem with the system there could be. Maybe someone replaced the camera on the windshield and didn’t put the bracket on correctly. But it’s also important that technicians understand this technology as well. In many cases the technician is the interface between the driver and the driver’s manager or safety person. So if the technician understands how the system works, when the driver has an issue the technician will know how to troubleshoot and repair the system.”

The negative alternative

If drivers are not up to speed and accepting of safety systems, it can lead to trouble.

“If you don’t listen to the driver then what you’re going to get is driver tampering,” warned Aller. “Drivers are smart. I go to YouTube to learn how to repair a faucet. They go to YouTube to learn how to tamper with safety systems. And we see this constantly. Someone will cut the wires going to a camera, or they’ll disconnect it. A business card will slide behind a camera. We know that because I’ve seen an accident video and the video was the business card.

“Through YouTube they have learned how to go to the steering-angle sensor and disconnect it. I have seen them take aluminum foil and put it over the radar. I’ve seen them take the cover off the radar, put aluminum foil behind the cover and put the cover back on.

“With the lane departure switch, they will push it in, take a piece of paper and stick it down in there so it doesn’t work.

“They will unplug speakers. The smart drivers will put them back together before the truck comes back into the shop. Some of them forget and we catch them. So when we release new technology it’s important that everyone is trained. If we don’t get driver buy-in today, we’re not going to get driver buy-in tomorrow.”

Older drivers in older trucks also present challenges. Those truckers need to be taught whatever new technology they must deal with.

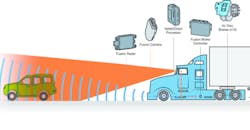

“Some fleets keep their tractors for a long period of time,” said Aller. “They’re taking some of the technology that’s available today and retrofitting their existing truck fleet. Some are doing lane departure, some are doing the collision mitigation system. So retrofits are growing in popularity.”

About the Author

Michael Catarevas

Michael Catarevas is a former managing editor at FleetOwner. He wrote for the publication from 2017 to 2020.