How digitizing driver communication can improve maintenance

Frequent topics of conversation in the commercial vehicle industry revolve around the adoption of new vehicle technologies – the driving force behind such conversations being that spec’ing technology throughout the vehicle can help optimize performance, reduce costs, and create a more efficient operation. Though seemingly left to the wayside of such conversations is the adoption of technologies from an organization’s operational standpoint: There are technologies to incorporate in a fleet’s organization that go beyond vehicle specification which can impact the way those interacting with the vehicles carry out their responsibilities.

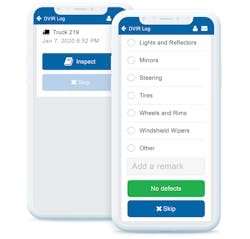

Driver vehicle inspection reports (DVIRs) are one such example. Abandoning the pencil and paper method of yesteryear and incorporating a digital platform to execute such a process can reveal profound efficiencies for a fleet’s organization across multiple departments.

Building an eDVIR

Filling out a DVIR is second nature for drivers today. Transferring to a digital process allows for some customization and flexibility in the way in which DVIRs are completed. There are many ways in which fleets can establish an electronic driver vehicle inspection report (eDVIR) system. First, a fleet must have an idea of what they want their eDVIR to include.

“Most of the things you are looking for in an eDVIR is anything safety-related, anything that could result in a citation, anything that could impact the safety, the reputation, and the relationship of the company to its customers, drivers, and the community in general,” said Ric Bedard, CEO and founder of Cetaris.

“There are specific items that are required by the Department of Transportation that must be inspected,” said Kevin Aires, global leader of product success at Verizon Connect. “But, above and beyond that, it is really important that businesses think about what else makes their fleet safe. That depends on the company and what they do and the services they provide customers; that could depend on the types of vehicles they have.”

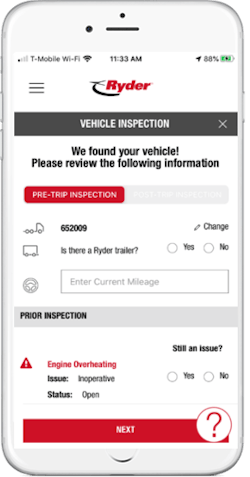

“A lot more [queries are raised] around the battery, some questions that we wouldn’t be asking in a diesel situation, but we need to be asking those upfront depending on the vehicle,” Mike Bosch, senior director of digital technology at Ryder, explained of RyderGyde’s eDVIRs.

“As we are getting more and more mixed fleets, and over time I think we will have a mix of both EV and diesel, as well as some other alternative fuels out there, we have really been focused on the experience of how we can consolidate that and make that a single experience across the board for the drivers and for the fleet managers as well,” Bosch said of standardizing eDVIRs according to vehicle-type.

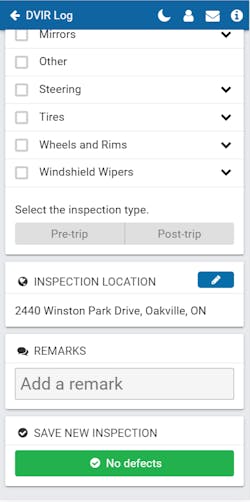

Trimble Transportation offers flexibility in the form of adjustable template reports.

“You can have different inspections for different types of vehicles,” said Renaldo Adler, industry principal – asset maintenance for Trimble Transportation. “The inspection for a tractor is different than the inspection for a trailer, it could be different for a service truck or a pickup and delivery, versus a Class 8 tractor and trailer, or a flatbed, the list goes on … [The DVIR] can be customized by the customer by the type of equipment they are trying to inspect. [DVIRs are] provided through templates, and then you can add to and change those.”

Teletrac Navman’s eDVIR solution, within the TN360 Platform, offers customization options. Furthermore, there is the ability for fleets to create their own templates to assign to specific assets.

“Say you have a crane truck, and a crane truck has a bunch of different items that your normal truck doesn’t have because it is outfitted differently,” said Oswaldo “Ozzie” Flores, product manager at Teletrac Navman. “As an organization, you can go in there and customize [the DVIR form], add those additional fields, and save that as a template.”

Inspection checklist customization is a critical component for fleets to remain agile in establishing safety reports according to their current needs.

“What we saw during the pandemic is that safety took on a new meaning,” Aires stated. “We think about safety for our drivers in terms of road safety, but all of a sudden, companies started thinking about the safety of my employee in terms of their health. We saw a need for companies to start using that customization aspect around inspections to incorporate things like vehicle sanitization.”

Verizon Connect’s reaction was to deploy a pre-configured sanitization template that fleets could incorporate into their eDVIR checklists.

Whether adjusting to changes in the needs of inspection, or accounting for different operational needs across a diverse fleet, having access to various reporting forms is crucial. Take, for example, fleets operating under varying DVIR mandates internationally between the U.S. and Canada, or across varying Canadian provinces and territories. Geotab accommodates such a need by providing different templates for U.S. and Canadian fleets.

“[With Canadian DVIRs], we can automate it for [customers] and set it up for what is necessary for them,” McInnis said of standardized DVIR forms. “We base it off of the license plate of the vehicle. If you have vehicles in several different provinces, as long as that [information] is populated in our system, then you will get the appropriate form. You can still customize your defects list, for example, but anything that is required on the report we will at least show you and give the driver the opportunity to enter that information.”

Customizing a report to capture the information required according to a fleet’s needs is one thing, but having the ability to determine the level of severity for defects on a report offers another level of customization which can establish prioritized action items for the organization as a whole.

“We have different severity levels, major and minor,” McInnis said of Geotab Drive’s defect designation capacity. “We also offer a third severity called ‘regulated’ in our system. That is usually stuff [like] a tear in your seat. It might not be super interesting, but at some point, it might need to be repaired. It may not impact the safe use of the vehicle, but still needs to be noted down.”

The severity level designation for each item on the checklist is defined when the checklist is created, not when the pre- or post-trip DVIR is created, McInnis clarified, which means a driver cannot flag comfort or amenity defects with out-of-service severity.

Dissemination of information

The digitization of DVIRs changes the way various departments within a fleet receive, digest, and act upon the reported information with an emphasis on speed via real-time notification systems, prioritization alerts, and customized reporting configurations.

“The whole point of a DVIR is for the driver to sign off that these are the things that are wrong with my assets,” said Cetaris’ Bedard. “The next step is transmitting that to the company, to have a technician who also must sign off to say that they have performed the repair and that it is completed, and then the final stage is for the driver to sign off that the repairs were completed to their satisfaction.”

“Everybody wants information right now,” Teletrac Navman’s Flores said. “Being able to have that real-time notification and real-time alerting is a very valuable feature for customers. Not only that, but it cuts down on having to go through and run reports and do reactive management rather than proactive. Proactive management leads to better efficiencies and better safety.”

Communication is key—and sharing the data gathered from eDVIRs to the appropriate parties is what creates communication expressways that organizations can lean into in order to expedite the sharing of critical maintenance data. Most eDVIR providers achieve this through offering customers the ability to customize, personalize, and organize their own notification system.

“It is infinite in the amount of context that you can add to the alerts,” Flores said of Teletrac Navman’s eDVIR solutions. “If you have, say, third-party mechanics that do your work for you, you can have their email addresses entered and they get notified as soon as a defect is found. And conversely, when a repair is made, they would get alerted as well.”

The concept of something as simple as a valid email address being the key to providing real-time actionable data insights, allowing for a fleet to know exactly when, where, and what is going on with a vehicle, provides an eye-opening opportunity to establish efficient communication processes.

“Within the Director Platform, we allow administrators to configure alerting based off what they found as far as the safety effecting defects. That alert can be sent to whomever it is in the business that needs to be informed of whatever issues that were found,” Flores further explained.

Notification information can include defect details, timestamps, location data, and more, Flores noted.

“From there, the people who are notified can take proactive action to set up a maintenance call to get it taken out of service and put in the line to get repaired,” he continued.

Creating a full-circle loop is an important consideration when establishing these lines of communication to ensure transparency and accountability so that all involved parties remain informed throughout the entire process from report to repair to confirmation of service.

“You cannot get that kind of interactive communication between all the players in a paper format,” Trimble Transportation’s Adler emphasized. “You have three-way communication from the driver to maintenance to operations of what is going on with that truck based on the eDVIRs.”

Data access, management, and integration

One of the most critical differences between the paper and pencil method compared to digitized DVIRs is the dissemination of that DVIR information to others in the organization beyond the driver after the report enters the system. How that information is transferred and then accessible varies by provider solution. This includes user interfaces and web portals that provide holistic views of a fleet’s assets, and details of specific vehicles and their status. Furthermore, the customization and selection of where this information is sent, as well as who has access to it, can be adjusted to the needs of an organization.

“The whole planning process is critical and having the information to allow you to keep the asset rolling is absolutely essential to have real-time, high-speed delivery,” Cetaris’ Bedard said. “That means the entire delivery chain of data has to be tuned as close to real-time as possible.

“You have the onboard hardware; it is connected to the ECM; it is connected to sensors; it is pulling the information off of [the] engine CAN bus,” Bedard continued. “That data is then funneled to us in varying formats through an API.” An Application Programming Interface (API) is a software intermediary that allows two applications to communicate with one another.

“Different styles and types of integrations are used today, but generally with the API … that data gets pushed up to a website using either cellular networks or satellite networks, depending on the trans communication media used by the individual platform providers or solution providers,” Bedard explained. “Once it gets to that site, then we would pick up the data there … we then take that information and we have a real-time dashboard that is configured depending on the role you are in. If you are in the role to be watching for work to be completed, you would have a dashboard that would include an eDVIR. It would include maybe PMs that are due, different categories of work, [et cetera].”

Dashboards provide a centralized access point for data sharing and reporting and are a familiar way for fleets to digest information.

“As part of providing a mobile workforce management solution, it is critical that drivers, fleet owners, dispatchers, safety managers, and mechanics all have access to a platform that really unites their fleet management strategy,” said Verizon Connect’s Aires. “As part of that, we deliver various mobile apps and web-based software, [such as] something you can pull up on a browser and log into from anywhere with an internet connected device. That ultimately allows all sorts of information to be at anyone’s disposal so that they are communicating efficiently about not just the status of vehicle inspection reports, but also location information, safety information, maintenance information, access to dash cameras and harsh driving events, those sorts of things.”

Flores advised Telematics Navman’s reporting data is accessible via a web portal. The company’s data management strategy allows for various reporting options, including reports available in Microsoft Excel and CSV format.

Gathering data and sending it to a dashboard for a fleet’s access can go beyond a single application with the incorporation of APIs. Many eDVIR providers utilize such a strategy to incorporate various data sources.

“Geotab Drive works using cellular service,” McInnis explained. “Once the driver creates that DVIR, it will be sent to the backend portal using that service. Then once it is there, there are several different options on how you’d want to distribute that, but by no configuration whatsoever – it is available to anybody that you provide access to that back-office portal.”

Open APIs allow the fleet to share eDVIR data with third parties, including transportation management software (TMS), to automatically populate information into these systems, explained Scott Sutarik, vice president of commercial vehicle solutions at Geotab. “MyGeotab is the user interface the back office would use [to view and access the data],” he said. “We have a variety of integrations using Geotab’s open APIs. This data is available to third parties, including with TMT [from Trimble Transportation], and several others that pull our APIs and then bring it into their system. They can create work orders and a whole host of other different things within their system, but essentially, they can go back and forth through those integrations between the driver and their work order management software. We also have integrations with various rental and lease companies, like Ryder and Penske.”

RyderGyde provides data management and access in various formats to accommodate end-users of different positions with specific needs.

“There is a web portal aspect of it, which is much more geared towards the fleet managers, dispatchers, some of those folks that need the macro-level view of the fleet,” said Ryder’s Bosch. “The fleet manager can log into RyderGyde.com and see the history of all the vehicles and all the DVIRs there.” RyderGyde is also accessible via an Android or iOS application. Furthermore, Ryder provides on-site kiosks at various Ryder locations for users who prefer such a format.

Ryder also integrates a suite of APIs into their data systems.

“Whether it is a shop system, our data warehouses, our CRM systems, our accounting system, all that is encapsulated around this set of APIs, which is what these front-end devices typically interact with in getting most of the data from,” Bosch explained.

Through its suite of APIs, Ryder integrates with many telematics providers.

“Geotab, Zonar, PeopleNet, and Omnitracs are a few that we are already integrated with,” Bosch said. “When you register for RyderGyde, you can enter your telematics providers and if it is one that we currently support that data starts flowing in instantly. The experience is obviously much better for a driver when you are doing these eDVIRs, launch RyderGyde, and start clicking through and it has dragged all that data over.”

Two-way communication through RyderGyde and their supported telematics providers is an advantageous aspect.

“One of the challenges there is that every telematics provider is a little bit different in how they use the data, or store the data, or transmit the data,” Bosch stated. “Our challenge is for every additional telematics provider we bring in, we make sure to normalize that data, even to a level where a mixed fleet might have two or three different telematics providers. For our customers, we want the experience to be exactly the same regardless of the provider.”

Operational overhaul

Understanding the challenges fleets may face during the implementation process ahead of time, and how to curb such challenges or apprehension, can result in the successful adoption of an eDVIR information network.

Benefits of eDVIRs

It is useful for a fleet to understand the possible benefits that can be reaped through the digitization of DVIRs.

“The benefits are velocity – the speed with which you can react to issues,” Cetaris’ Bedard stated. “Things are being reported [in] real-time; it gives your team more time to assess, adapt, address, and resolve. As an organization, it gives you much better control … It is tying all those things together so that the flow of data, the digitization of all of this data, leads to better efficiency, better visibility, better responsiveness. You can be more effective at what you are doing in your business.”

Not only is the speed of communication increased, but so are the physical inspection processes.

“By moving to an electronic DVIR, you are ultimately allowing your driver to get on the road quicker, which of course impacts the business in terms of on-time delivery and therefore customer satisfaction,” Verizon Connect’s Aires said. “Giving drivers a tool that is easier to use, potentially even automated, customized to the type of information that needs to be collected, is a benefit of moving to a digital version.”

Clarity of communication is also increased through digitization.

“Going digital also provides a certain opportunity to have less room for errors,” Aires continued. “Digital forms are going to be easier to use. It is going to be more legible. This improves the entire operation of the business, reducing the time that it may take for the back office to have to verify some of the information or potentially re-communicate and get in touch with drivers to ask questions. By bringing it digital, it reduces a lot of those errors that you may see on the paper side.”

Reports will be cleaner, and so will the sharing of reports – particularly for drivers.

“You are not having to go out, get a piece of paper, fill it all out, make sure you hold on to it, turn it in at the end of the day, make sure it is in the right slot, grab the new one, look at that one from an old driver, hope you find it in the cab of the truck, those kinds of things,” Teletrac Navman’s Flores said of the paper and pencil DVIR method. “When it is electronic, it is literally right at your fingertips. If you can articulate the value of what it is that that tool is meant to do, then you can climb that mountain a little bit easier,” he continued, speaking to driver adoption.

eDVIRs also establish accuracy and legitimacy in reporting practices.

“There are bad habits that can result from paper-based forms,” Aires warned. “Habits [such as] simply checking the box, or there is something that drivers have been known to do, which is what I’ll call ‘batch-filing’ of reports – basically filling out all of your inspection reports the last day of the week when you are returning to the office and you are handing over a stack of DVIRs, ultimately not doing them in the moment, but doing them at the very end. The immediate on-time nature of a digital form is going to prevent some of those bad habits.”

Additional safety nets of the reporting process are integrated in some eDVIR offerings.

“[The driver] has to do that pre-trip inspection before it will let him basically go on his trip,” Adler explained of Trimble Transportation’s built-in safety feature within their eDVIR solution. “He can’t leave with the truck unless he goes through the inspection.”

Adjustments can be made to establish best practices going forward once digital reporting structures are in place. If a better way of doing things is revealed to a fleet through the use of eDVIRs, the fleet can implement that new process immediately.

“If eDVIRs are coming in and they are getting real-time reported, and if there is a regulatory issue that you were written up for, this would allow you to assess that and change your inspection checklist,” Bedard posed. “From that day forward, or from that millisecond forward, once you make the change to your daily inspection, that would not be missed because it would be part of your inspection process.”

Challenges and how to curb them

Doing things in a drastically new manner can certainly be challenging. This is not lost on eDVIR solution providers, as they express common pain points that may arise in the adoption of a new technology and offer practices to realize a successful implementation.

“I think, probably, the biggest challenge is buy-in,” Geotab’s Sutarik said. “Working with the drivers, getting their feedback, and making sure that they are trained properly … Everything is about habits and getting them to go from A to B is a challenge.”

Driver buy-in is the first hurdle to cross. Introducing a new technology can be difficult, but ensuring that the technology’s platform is not a foreign concept can expedite adoption. Taking eDVIRs into mobile devices reinforces such an approach. By not introducing a foreign tablet that has its own operating and navigation system (which could cause another level of complexity for adoption) and, rather, using familiar devices and processes can help new users quickly adapt to eDVIRs. The initial user experience is going to help users stick the landing of getting over the hurdle of technology adoption.

“We are really focused, at Ryder, that the experience is intuitive,” Bosch emphasized. “That it is easy to use, at a minimum. It has to be on par with the paper approach, and ideally, it is much better so that the adoption is something that the customer is accepting, and it is not just forced on them.”

People today have general expectations as to how a mobile application experience and navigation should look and feel.

“One of the places that we put a lot of focus in is making sure this experience works 100 percent of the time,” noted Bosch, in reference to the RyderGyde mobile app. “We are really trying to empathize with the users and empathize with the drivers. Put yourself in the driver’s shoes: It is the first time somebody told me to do [a DVIR] digitally and I am already a little bit hesitant, possibly. If I go through the experience and it just doesn’t work, well we really have one shot to get them to use it, and understand it, and be happy with it, because as soon as it fails, [a driver] will just go back to paper. We are putting a lot of effort in to avoid those types of situations.”

The goal for any deployment of new technology is that the user can pick it up and use it immediately and do so seamlessly.

“We have a huge focus on user experience in general,” Aires said of Verizon Connect’s approach. “We employ quite a large team whose sole role is to make it easier for our products to be able to be used.”

Though if an eDVIR is so simple to use, will drivers be able to “cheat the system” and simply click away on their device? A sort-of digital pencil whipping? Solution providers have considered this as well.

“Our mobile app utilizes something that I will call smart detection software,” Aires stated. “It actually helps ensure that the driver has physically walked around and inspected the vehicle. In addition to going through a checklist, that mobile technology is also doing a check using accelerometers in the phone, ultimately detecting and verifying that that driver has gone outside the vehicle and done his or her inspections … We have employed mobile detection technology that does provide an extra layer of verification to the inspection report, ultimately giving the back office a little bit more peace of mind that those inspection reports are coming back to the office and they are legitimate.”

Another apprehensive perspective fleets may have before taking on the digitization of reporting is a concern regarding integration of multiple devices and systems.

“I think a challenge is getting all the products to talk together,” Trimble Transportation’s Adler cautioned. “There are a lot of telematics solutions or DVIR solutions, and from that standpoint, making sure they can communicate with all your business units, it may require developmental work,” he continued. “Trimble offers a full-service system and covers all the bases. Make sure that everything is connected upfront rather than having to invest in some developmental work on the backend as well.”

Choosing a provider is one challenge in and of itself, so fleets should come into the adoption and selection phase with a plan of what data they are really looking to get out of such a platform. The concern of drowning in data is real, but providers are acutely aware of tailoring systems to ensure data is targeted and useful.

“It can create noise if it is not properly rolled out,” Cetaris’ Bedard warned of eDVIR adoption. “Data quality is a big one. You have to have data set up effectively. You have to make sure that [you differentiate] the serial numbers on the telematics devices – that is how to uniquely identify unit number one versus unit number two versus unit number three – that data all has to be right … We have got to get rid of the noise; we can’t give [users] a tsunami of data. You have to filter it down and focus on actionable items. People not using the eDVIR as intended will create noise, but I think if you communicate well and you work with your team well, you can turn it into a very powerful tool.”

Deployment of a system can be overwhelming, though most providers will offer support and guidance in that regard. Depending on the solution provider, fleets may have access to in-person, in-application, or video training, as well as access to customer call centers.

The future of digital reporting

“With our TN360 solution, one of the focuses is on AI (artificial intelligence),” Teletrac Navman’s Flores explained. “That is where we are focusing on heavily, and that is going to tie into our compliance solutions as well. Eventually, that will tie into the vehicle inspection reporting solution … Providing advanced intelligence based on trends that you see as a fleet from inspections and repairs so we can start to alert people predictively. The users then can use that information to look back and say, ‘If this is becoming a trend, how do we get in front of it?’,” he continued. “Those are the kinds of things that are coming in the forefront, as well, for us.”

Solution providers’ ability to capture eDVIR data will be one of the building blocks in creating the predictive algorithms that analyze a fleet’s generated data and subsequently present the predictive models that maintenance managers dream of.

“We are doing a lot more experimentation around predictive data models and machine learning,” Ryder’s Bosch said. “Data is so important. There is so much of it right now, but how can we use that data to create predictive insights for fleet managers? The possibilities are endless once you have that data, to be able to say, ‘This type of vehicle seems to always have this type of issue around this type of mileage.’ A hypothetical like that gives us so much more information than we had before.

“With the data availability, but then also being able to combine it with other data, too, we have become more mature in our big data analysis and what we want to do with it,” Bosch continued. “Bringing in weather conditions or bringing in other aspects that may have affected [a vehicle], [we are able to contemplate] how can we predict what the next eDVIR will be for this particular vehicle.”

Data accumulation and data accuracy will be the guiding hand in building a predictive maintenance future.

“This data is extremely valuable for any fleet,” Bosch noted. “The more information we have, and the more accurate it can be by [obtaining] it through a digital means, the more active we can be with our insights and our predictive models … [The data gathered from eDVIRs] is the source data and training data that really pushes us out into predicting and understanding the current health of a fleet, but then even six months from now what a fleet manager can be expecting as well. It is very valuable data and I think creating a positive experience to make sure that we are getting the data is critical for success.”

What is the goal of predictive maintenance models if not a maximization of uptime?

“Advanced organizations are trying to maximize equipment availability,” Cetaris’ Bedard said. “If you can coordinate hours of service when the driver is driving and when they are not driving, versus the opportunity to do repair, if you can optimize that so all the repairs are being done when the asset is not required – think about the implications of that from a driver satisfaction perspective, a planning perspective.”

The ultimate achievement delivered through the digitization of DVIRs is not express communication, predictive analytics, nor uptime, but truly actualizing the safest driving operation possible.

“The DVIR is one piece of a broader theme, which is, ‘How do you build a culture of safety within a company that is operating vehicles?’” Verizon Connect’s Aires posed. “How do you get drivers to really buy in to that safety culture where they become advocates for safety; where they are excited to take on new technology, new processes, or new tasks in order to benefit the company, the customer, and the community that they drive in, to make it a safer journey for them, and ultimately give the company the opportunity to put their best foot forward as a business?”

Electronic DVIR platforms

Should a fleet decide to ditch the pen and pad and adopt electronic driver vehicle inspection reports (eDVIRs), there are plenty of options available to choose from; selecting the appropriate solution depends on a few factors regarding the fleet’s composition and existing assets.

“If I am not using a paper and pencil, then what will I be using?” a fleet might ask. It depends. If there is a cab-mounted electronic logging device (ELD) in the vehicle, chances are it has the capacity for eDVIR integration. Beyond the ELD however, there are options to incorporate a mobile device to carry out driver reporting.

ELD-integration

Teletrac Navman | Director Platform

An in-cab tablet has the option to perform eDVIRs separately or to integrate with the ELD.

Geotab | Geotab Drive

Users can enable DVIRs within the ELD workflow solution.

Verizon Connect | ELD-integrated offering

A “simpler” eDVIR offering, typically used by small businesses, that is a standard checklist integrated into the ELD.

Mobile application

Trimble Transportation | TMT Fleet Maintenance

A standalone application that can be used by drivers to complete eDVIRs.

Verizon Connect | Mobile app

The company’s flagship eDVIR solution deploys customizable safety checklists.

Ryder | RyderGyde

RyderGyde is Ryder’s platform for eDVIRs, based on a mobile application for drivers’ use.

Teletrac Navman | TN360 Platform

A flexible, customizable eDVIR solution delivering adjustable reporting templates.

Cetaris | Mobile application

A feature-rich mobile app that offers customizable reports and inspection programming.

About the Author

Tyler Fussner

Assistant Editor | Vehicle Repair Group

Tyler Fussner is a former assistant editor for Endeavor Business Media's Commercial Vehicle Group, including FleetOwner and Fleet Maintenance.