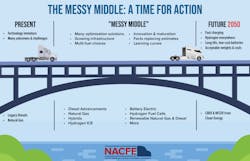

As we move through trucking’s messy middle, I am going to ask truck manufacturers to exercise restraint. I am saying this regardless of what the powertrain options are on the trucks they are selling.

While the right truck for the right application has always been important for trucking, as we navigate the messy middle it is critical that trucks be application-specific going forward. The wrong choice of vehicle can have long-term impacts on a fleet’s operation and can make them less willing to try new technology in the future.

We are seeing a plethora of powertrain options either already on the market or in development. Other than diesel, there is not one powertrain option that is right for every scenario. And diesel does not address the sustainability issues that many shippers have now committed to.

See also: A framework for choosing powertrains in the 'messy middle'

For the first time in a long time, and for some time to come, fleets are going to have to choose what fuel and powertrain design they want powering their trucks. As a result of that, I think truckmakers and their dealer networks are going to have to take on more of a consultant role. And in that role, they must be willing to tell a fleet if they don’t have an option that fits their needs. Be transparent and truthful about the technology’s benefits and challenges. Don’t force a round peg into a square hole.

Given the R&D costs of bringing a new truck and powertrain to market, I don’t think that going forward every manufacturer is going to have every powertrain option in their product portfolio. And it would be a great disservice to a fleet to try to talk them into a powertrain that is not well-suited for their application. For example, today's battery-electric vehicles in long-haul applications are not practical. Their limited operating range and lack of a nationwide charging infrastructure make BEVs unsuited for long-haul. On the other hand, they are a great choice for terminal tractors, van and step van applications, box trucks, and even short regional haul.

When meeting with manufacturers and dealers, fleet managers need to be willing to share the operating characteristics of their fleet to make sure duty cycles and powertrain options match up properly. It is likely that, as we work through trucking’s messy middle, fleets will be operating with more than one fuel source for their trucks. I am hoping that manufacturers will help fleets optimize their choices, and that might mean having to walk away from some business because they do not have a powertrain option that fits the fleet’s needs.

The messy middle needs to be a time of cooperation, collaboration, information sharing, and transparency where fleets, manufacturers, and dealers work together to lead us to a cleaner freight future.

Michael Roeth has worked in the commercial vehicle industry for nearly 30 years, most recently as executive director of the North American Council for Freight Efficiency (NACFE). He serves on the second National Academy of Sciences Committee on Technologies and Approaches for Reducing the Fuel Consumption of Medium and Heavy-Duty Vehicles and has held various positions in engineering, quality, sales, and plant management with Navistar and Behr/Cummins.

About the Author

Michael Roeth

Executive Director

Michael Roeth is the executive director of the North American Council for Freight Efficiency. He serves on the second National Academy of Sciences Committee on Technologies and Approaches for Reducing the Fuel Consumption of Medium and Heavy-Duty Vehicles and has held various positions with Navistar and Behr/Cummins.