First look: DTNA’s Detroit Gen 6 engines tackle EPA 2027 with focus on fleet fuel savings

Key takeaways

- EPA 2027 compliance and fuel savings: DTNA’s new Detroit Gen 6 diesel engines (13-, 15-, and 16-liter options) meet strict 2027 NOx limits while delivering an estimated 3% fuel-economy improvement for linehaul fleets.

- New Pre-SCR technology: A novel pre-Selective Catalytic Reduction (pre-SCR) system helps engines reach operating temperatures faster, significantly reducing the need for parked regenerations during low-load operations.

- Zero changes to maintenance intervals: Built on the proven Heavy-Duty Engine Platform, the Gen 6 architecture ensures routine service intervals—including oil maintenance and DPF cleaning—will remain unchanged.

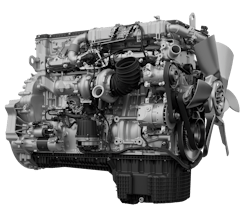

DETROIT—As the trucking industry braces for EPA 2027 emissions mandates, Daimler Truck North America (DTNA) has a new generation of compliant heavy-duty engines built on familiar, proven architecture that its leaders say fleets will find familiar while also improving fuel efficiency.

“We have an incredible engine platform to begin with—we like to say we're the envy of the industry in terms of our Detroit powertrain,” David Carson, DTNA’s SVP of sales and marketing, told FleetOwner after his team unveiled the engine during an industry media event here at the historic Detroit Manufacturing Plant. “It's served us and our customers extremely well up to this point, and starting in 2027, we do have a new emission standard—but we've offered in this new engine, the Gen 6 Detroit series engine, additional value for our customers in terms of efficiency and an overall value in terms of their ownership.”

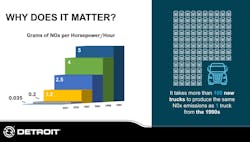

The new lineup of DTNA’s Detroit-branded Gen 6 diesel engines will be available in 13-, 15-, and 16-liter options that meet the EPA’s looming 35-milligram nitrogen oxide (NOx) limit. While greenhouse gas provisions originally attached to the 2027 regulations were eliminated, OEMs are still awaiting clarity on other regulatory aspects. However, with nearly seven years of development already invested in the Gen 6 platform, DTNA leadership stressed that they are moving forward with the offering across its Freightliner and Western Star brands regardless of what the EPA does next.

“The useful life and warranty coverage is not yet officially resolved,” Carson noted. “We expect the administration is working on that, and they will ultimately remove that requirement.”

Detroit Gen 6 engines: EPA 2027 compliance and fleet fuel efficiency

The Detroit Gen 6 DD13 and DD15 engines will be available in January 2027, with Gen 6 DD16 production following a year later.

With more fleets postponing equipment refreshes amid the freight recession that has hit carrier profits for more than three years, the new EPA '27 regulations could spur a small prebuy for fleets looking to get ahead of the more expensive tractor prices next year.

Carson is urging fleet customers to manage their replacement cycles carefully to avoid industry-wide equipment capacity constraints if there is a rush on Class 8 orders. He noted that DTNA wants to ease the industry’s transition to the new regulatory era by assuring fleets that Detroit’s Gen 6 Heavy-Duty Engine Platform (HDEP) will be familiar to technicians and drivers, as it’s simply a refinement of the same 1.2 million Detroit diesel engines already operating in North America since 2007.

While Carson said DTNA is not ready to publicly discuss 2027 prices, he acknowledges that any emissions-driven update will increase equipment costs. But he said that Detroit’s multi-year engineering investments aren’t just about reducing NOx—it’s about tangible bottom-line returns for fleets.

"Look, if you were paying more money for just an emission standard, then I could understand you being very frustrated," Carson said. "But if you pay more money for the next generation of engine that is meeting that emission standard and provides value in terms of its design and its efficiency ... we think that makes it a better value proposition for the customer."

That value is anchored in an estimated 3% improvement in fuel economy over the current powertrain for typical linehaul fleets—depending on driver behavior and idle times.

Under the hood: Detroit Gen 6 engine technical and aftertreatment upgrades

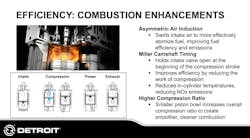

To meet EPA’s 82.5% NOx reduction mandate without compromising uptime or altering the vehicle, Detroit engineers targeted the engine’s combustion and aftertreatment systems.

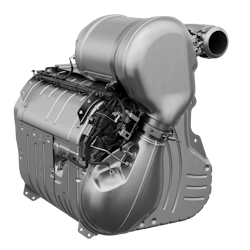

A new pre-Selective Catalytic Reduction (pre-SCR) system was installed upstream of the primary aftertreatment system (ATS), incorporating familiar elements of the main ATS. This helps the engine reach critical operating temperatures much faster. Paired with a thermal control valve, this setup improves emissions control during low-load operations and significantly reduces the need for parked regenerations.

The new ATS has no back-of-cab impact, preserving chassis space for vocational upfitters and truck equipment manufacturers. The Gen 6’s main one-box ATS also retains the Gen 5's outer shell, which should make it feel familiar to fleet maintenance technicians.

"The larger box that you see here ... is virtually the same unit that we're putting on our trucks today," Greg Braziunas, DTNA's head of powertrain engineering, explained during the reveal. "In general, it's the exact same outer shell. So it will be very, very familiar to our customers, both from a reliability and durability perspective, but also a service perspective."

Inside the engine block, Detroit introduced an optimized combustion package to deliver a 3% gain in fuel economy. Engineers redesigned the asymmetric intake port to increase air swirl and installed a Miller-cycle camshaft. By leaving the intake valve open slightly longer during the initial compression stroke, the Miller timing increases the compression ratio and overall engine efficiency.

The Gen 6 fuel system was also slightly simplified by moving away from a fuel-lubricated setup. The Detroit engines use an oil-lubricated high-pressure fuel pump and a high-pressure common rail (up to 2,500 bar) to enable simple, non-amplified injectors that deliver a higher, more consistent fuel flow throughout the engine’s lifespan.

Steve Collins, Detroit's director of field sales engineering, noted that the oil-lubricated pump is designed to withstand harsh operating conditions. "Our customers can't always control the quality of the fuel that they have access to," Collins noted. "Having a real, robust fuel system adds additional efficiencies and benefits to our customers in terms of robustness as well."

While these new systems are a technological leap, Detroit is ensuring the engines retain familiar power ratings that fleets rely on. The Gen 6 offerings also add three new ratings to Detroit’s powertrain suite—including two efficiency ratings for the DD15 (425 hp and 455 hp) paired with 1,900-lb.-ft. of torque. This unlocks additional downspeeding capabilities, allowing linehaul fleets to run the engine at lower speeds and work it harder to achieve fuel savings without sacrificing driver performance.

Vocational trucking fleets get more options with new DD13 ratings

While the on-highway trucking market continues to slog through the longest freight recession on record, the vocational sector is a resilient bright spot for DTNA, Carson said.

To support the heavy-duty side of the vocational market, Detroit introduced a new DD13 rating for customers seeking a 500 hp engine, following its Gen 6 new-but-familiar theme.

“If you're utilizing a Gen 5 engine today and you have a power rating that works for this, we have those same power ratings for Gen 6,” Collins said. “In addition to that familiarity, we're actually adding three new power ratings—one specifically on the DD13 for vocational customers who are looking for a 500 hp engine who weren't quite ready to leap up to 1,850 lb. of torque.”

Collins was speaking of the DD13 available in 505 hp/1,750 lb.-ft. torque ratings to bridge the gap for fleets that don’t need as much power.

Detroit is carrying over its thermal control valve technology—first launched on the Gen 5 DD13—to the Gen 6 DD15 and DD16 engines. Collins noted that this valve reduces or eliminates the need for parked regenerations in vocational vehicles that require high idle times and slow movements.

Detroit Gen 6 diesel engine reliability, testing, and fleet maintenance

Before the first Gen 6 engines reach new customers in 2027, the platform will have undergone nearly seven years of rigorous validation and testing, Braziunas said.

He said DTNA’s engineering teams pushed the new platform beyond standard compliance requirements with more than 60,000 hours of durability testing and more than 8 million real-world miles. Daimler’s test vehicles were subjected to environmental extremes and multiple season cycles. Those conditions ranged from -40 degrees F in winter to 130 degrees in summer.

Engineers also ran extended idle testing to ensure the new system complies with the EPA’s stricter emissions regulations.

While the latest generation of Detroit engines features complex engineering enhancements under the hoods of Freightliner and Western Star trucks, DTNA leaders said fleet maintenance staff should not expect new service hurdles.

Routine service intervals will remain unchanged in 2027, meaning technicians can follow the same oil maintenance and diesel particulate filter (DPF) cleaning schedules they use today.

"We've really optimized the entire system to meet the requirements and the changes that we had to do in order to meet the more stringent emission standard," Braziunas said. "But again, doing that, bringing out some efficiency, and really putting a high emphasis on reliability and durability."

About the Author

Josh Fisher

Editor-in-Chief

Editor-in-Chief Josh Fisher has been with FleetOwner since 2017. He covers everything from modern fleet management to operational efficiency, artificial intelligence, autonomous trucking, alternative fuels and powertrains, regulations, and emerging transportation technology. Based in Maryland, he writes the Lane Shift Ahead column about the changing North American transportation landscape.